As we stand on the brink of a technological revolution that will fundamentally alter how we live, work, and relate to one another, the future of robotics in manufacturing emerges not just as a possibility but as a promise.

This isn’t about distant dreams. It’s about the tangible transformation robotics is bringing to the manufacturing industry today.

In an era where robotic technology is no longer the stuff of science fiction but a key player in our daily operations, the implications are vast and varied. From enhancing productivity and quality to prioritizing safety and employee satisfaction, automated systems and robotics are reshaping the landscape of manufacturing across the globe.

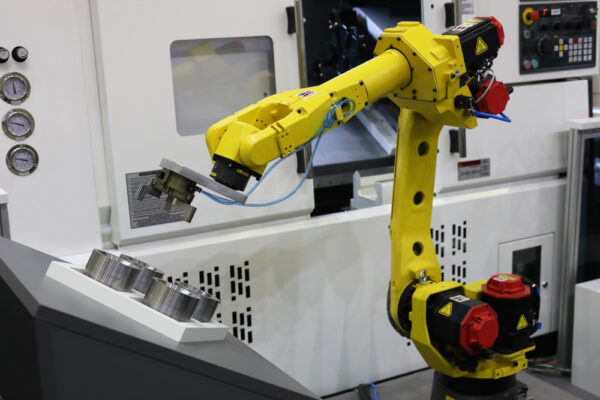

With advanced robot arms, custom machinery, and collaborative functions becoming increasingly commonplace, the question is not if but how quickly these technologies will become integral to your manufacturing processes.

As we examine the future of robots, it’s clear that their evolution isn’t just about improving efficiency but also about enriching human lives. Whether through increased revenue, better job satisfaction, or the creation of safer work environments, the integration of robotics in manufacturing holds the potential to uplift every aspect of the industry.

Stay with us as we look at the cutting-edge advancements in robotic technology and the unparalleled opportunities they present for the future of robotics in manufacturing.

Discover how your business can stay ahead of the curve by harnessing the power of automation to redefine what’s possible in manufacturing.

Targeted Automation

When we picture the future of automation, it’s easy to conjure images of fully automated, ‘lights out’ facilities operating in the absence of human intervention. These futuristic factories, tirelessly working around the clock, handle everything from sourcing raw materials to processing, packaging, and shipping products without a single human in sight.

While such a scenario may seem like the ultimate goal, the true future of robotics in manufacturing is likely to unfold through targeted automation.

Targeted automation represents a more nuanced approach. It’s about identifying specific processes within the manufacturing workflow that can benefit most from automation. This strategic integration of robotic technology ensures that automation supports rather than replaces the human workforce, enhancing safety, efficiency, and productivity without completely eliminating the need for human oversight and expertise.

Let’s look a little deeper into how targeted automation is paving the way for a new era in manufacturing, setting the stage for a future where robotics and human ingenuity work hand in hand.

Related Reading: Understanding Turnkey Automation

The Pareto Principle in Robotic Automation

The Pareto Principle, often referred to as the 80/20 rule, is a powerful concept that can be applied across various aspects of business and life. In manufacturing, it suggests a strategic focus: identifying and automating the 20% of your products that generate 80% of your growth and revenue.

This principle underscores the importance of targeted automation, where the emphasis is on enhancing the production of high-performing stock-keeping units (SKUs) through robotic technology.

By adopting this approach, manufacturers can experience what we might call a series of “awakenings” to the benefits of robotic automation. The selective automation of these key SKUs can significantly increase production capacity for growth-centric products.

Applying the Pareto Principle to the future of robotics in manufacturing doesn’t simply streamline operations. Instead, it strategically amplifies your investment, ensuring that resources are allocated where they can yield the highest returns.

As we look to a future where automation becomes increasingly nuanced and integrated, the focus on maximizing efficiency while minimizing waste will pave the way for smarter, more sustainable manufacturing practices.

Related Reading: When to Break the 80/20 Rule in Automation Integration

Packaging and Palletizing

End-of-line processes such as packaging and palletizing present unique opportunities for automation. While the idea of a custom robotic or machine solution might seem daunting due to its variability and the concern over practical return on investment (ROI), these tasks are ripe for robotic innovation.

Most products, irrespective of the industry, require standardized packaging for shipping, and pallets universally adhere to standard sizes.

This is where the magic of custom end-of-line packaging machines comes into play. Such robotic systems are designed to be product and industry-agnostic, capable of handling a wide range of packaging tasks with unparalleled precision and efficiency. Your investment in robotic packaging and palletizing solutions not only streamlines the packaging process but also significantly enhances the scalability and adaptability of your manufacturing operations.

Automating these final steps of the manufacturing process can lead to substantial gains in productivity, reducing labor costs and minimizing errors. More importantly, it can provide a scalable solution that grows with your production needs, ensuring that as your product lines expand, your packaging capabilities can keep pace without missing a beat.

By integrating robotic packaging and palletizing into the manufacturing workflow, businesses can unlock new levels of efficiency and performance, paving the way for a future where automation not only complements but enhances the entire manufacturing process.

Related Reading: Hardware Design Fundamentals

Revolutionizing Manufacturing with Pick-and-Place Robotics

Repetitive and ergonomically challenging tasks often lead to the highest rates of turnover on the factory floor. The introduction of pick-and-place robotics heralds a new era in addressing these challenges, aligning perfectly with the future of robotics in manufacturing.

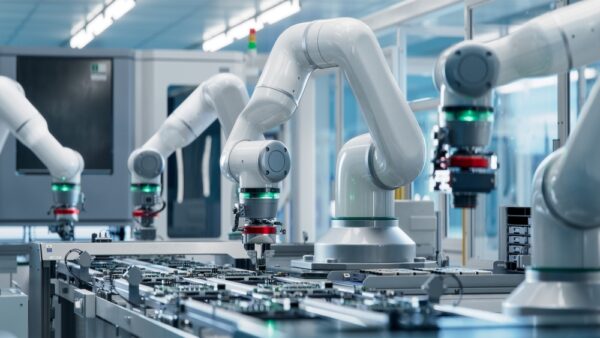

The goal is to boost high-volume PCBA efficiency by buying existing assembly lines and enhancing them with specialized automation in board handling. This approach spans automated feeding, trimming, post-assembly treatments, testing, packing, and palletizing, focusing on precision and labor reduction.

By applying proven assembly lines and targeting automation where it counts, they streamline production and reduce error rates for high-speed and high-volume PCB assembly.

These robotic systems excel in tasks requiring orientation and singulation, handling mass production duties with unmatched precision. The ability to consistently perform these repetitive tasks not only reduces the risk of ergonomic injuries but also ensures a level of productivity and quality that is difficult to achieve through manual labor alone.

By integrating robotic technology into your manufacturing process, you can significantly decrease turnover rates by alleviating the physical demands placed on the workforce. This strategic application of automation not only highlights the future of robots in industry but also serves as a testament to the transformative potential of robotic technology in enhancing the manufacturing ecosystem.

Related Reading: The Role of Programming and Testing in PCB Assembly

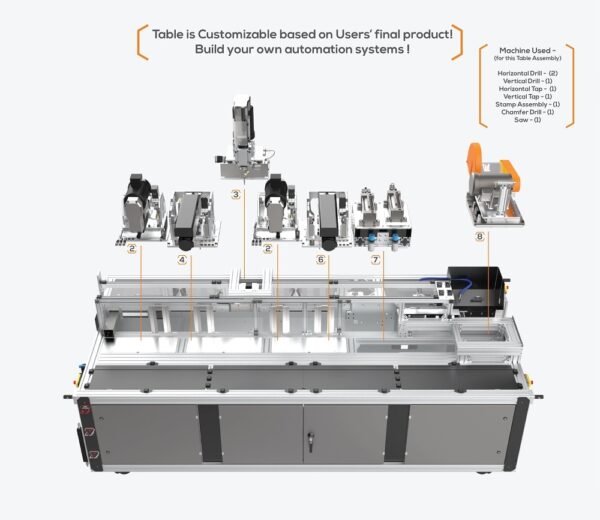

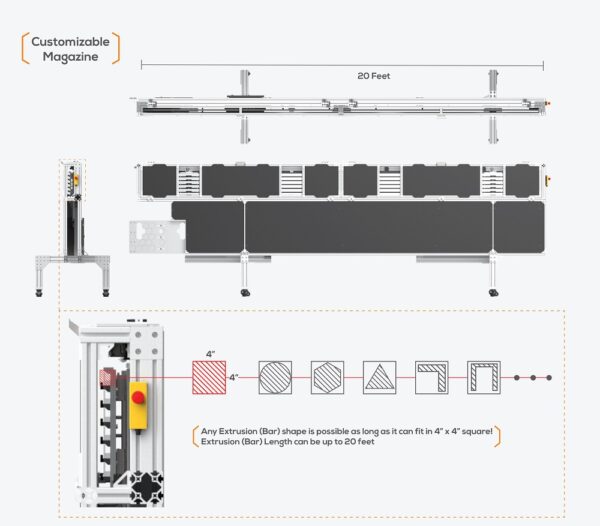

High-Volume Manufacturing with Modular Linear Transfer Machines

The advent of modular linear transfer machines marks a significant milestone in the future of manufacturing sector robotics. These marvels of engineering blend the bespoke nature of fully customized machinery with the adaptability of a modular system.

The result?

A powerhouse of efficiency capable of transforming raw material into finished products through a seamless series of automated tasks — cutting, stamping, modifying, and more — without manual intervention and free from errors.

In terms of robotic technology, modular linear transfer machines are a step towards more flexible, scalable manufacturing solutions. Designed for high-volume, low-mix tasks, these machines aren’t just about doing the job faster, they’re about doing it smarter. With the ability to swap out individual modules or effortlessly expand the production line by adding new modules, manufacturers can adapt to changing demands with unprecedented agility.

This future of robotics in manufacturing doesn’t just promise efficiency; it brings a new era of customization and adaptability. By integrating modular linear transfer machines into your operations, you can stay ahead of the curve, responding swiftly to market trends and consumer demands without compromising quality or speed.

Related Reading: Comprehensive Guide to Industrial Automation

Empowering Efficiency with Partial Automation

Full automation from start to finish isn’t always the most viable or cost-effective approach. Enter the concept of partial automation, a strategic, ROI-focused method that targets the most critical aspects of the production process.

This approach leverages custom machines or robots to address specific bottlenecks and risk points, seamlessly integrating with manual operations to enhance productivity without overhauling the entire system.

Partial automation is about smart investment and strategic improvement. By breaking down the construction of a product into module-based projects, manufacturers can not only address current inefficiencies but also lay a flexible foundation for future expansion. This allows the system to grow and adapt in lockstep with demand, ensuring that investments in automation pay dividends in both the short and long term.

Partial automation shows how robotic technology can be applied to augment human efforts rather than replace them. It’s a testament to the evolving relationship between humans and machines, where collaboration leads to greater productivity, enhanced quality, and increased employee satisfaction.

By adopting partial automation, manufacturers can enjoy the benefits of robotic technology where it counts the most, ensuring a balanced, sustainable approach to production that aligns with growth objectives and market demands.

Related Reading: How You Should (and Shouldn’t)

Calculate Your Return on Investment with Your Integrator

Tailoring Success with Custom Automation

While aspirational, the concept of a fully automated facility may not be immediately achievable for many businesses. However, the dream of a fully automated manufacturing line isn’t just a possibility but a reality within reach in today’s market.

This is where custom automation plays a transformative role, especially when integrated thoughtfully with robotic technology — a key player in the future of robotics in manufacturing.

Custom automation systems integrators stand at the forefront of this revolution, offering solutions tailored to target your production line’s most efficient and high-performing products. By leveraging off-the-shelf parts and advanced engineering options, these specialists create bespoke solutions that seamlessly blend established practices with cutting-edge proof-of-concept technology.

The beauty of custom automation lies in its scalability and adaptability. These bespoke machines are designed not just for the tasks at hand but with an eye toward future expansion. They pave the way for integrating secondary process automation opportunities, such as packaging and palletizing or machine tending, further improving operational efficiency and productivity.

As we look towards a future shaped by advanced robotic technology, custom automation is a testament to human ingenuity, bridging the gap between today’s needs and tomorrow’s possibilities.

Related Reading: Arguments That Shouldn’t Hold You Back

from Automating Your Manufacturing

Better Technology Overall

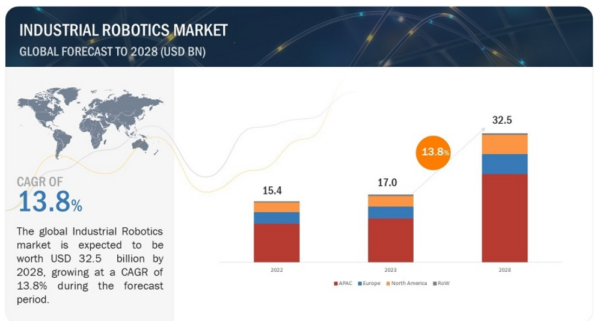

The fast-approaching future of robotics in manufacturing means we’re not just moving toward faster and more advanced technology. We’re also stepping into an era where innovations redefine the very fabric of production. The pace of technological evolution is so rapid that what’s cutting-edge today might be seen as outdated tomorrow.

This relentless progression underscores the critical role of robotic technology in shaping a more efficient, precise, and sustainable manufacturing landscape.

Energy Efficiency: Green Automation

In the future of robotics, energy efficiency stands at the forefront of technological advancement. The trend is unmistakably towards systems that not only consume less power but also champion standardization and efficiency.

As green, renewable energy sources gain ground against traditional fossil fuels, the manufacturing industry is poised to become a high-volume source of sustainability. This shift not only aligns with global efforts to combat climate change but also offers a competitive edge in a market increasingly sensitive to environmental concerns.

Interoperable Technology: The Dawn of Connected Manufacturing

The integration of the Industrial Internet of Things (IIOT) with data collection, monitoring, and AI-assisted actions is already transforming the landscape of manufacturing technology. These interconnected systems enable unprecedented levels of efficiency, offering insights that can pivot business strategies and enhance network control across multiple facilities.

The goal is to harness the power of remote diagnostics, support, and data tracking. By allowing a seamless flow of information, any potential issues can be identified and addressed promptly, without the need for on-site visits.

This not only cuts down on downtime but also means a continuous refinement of processes based on data-driven insights. The ability to remotely update and maintain manufacturing technology just highlights how interconnected systems aren’t just enhancing operational efficiency but also paving the way for a more adaptable and resilient manufacturing ecosystem.

Imagine a COO orchestrating manufacturing lines worldwide, wielding real-time data instead of outdated reports to make informed decisions. The move towards remote support, updates, and maintenance through internet-enabled plans is redefining what it means to manage and upgrade manufacturing technology.

Precision: The Quest for Perfection

The relentless pursuit of precision in manufacturing has meant robotic technology is setting new standards for quality, consistency, and efficiency in manufacturing. Fueled by a continuous wave of invention, innovation, and the application of new materials, the future of robotics promises not just improvements but transformations that will redefine manufacturing excellence.

This path to perfection isn’t just about enhancing what we make but how we make it, ensuring that the future of manufacturing isn’t only more efficient but also more adaptable and resilient.

Related Reading: How Industrial Automation Saves You Money

Investing in the Future: The Evolution of Robotic Costs

The trajectory of robotic technology in manufacturing isn’t simply shaping the future of production but also redefining the financial strategies behind adopting such innovations.

Historically, the capital investment required for custom robotic and machine systems has been substantial, similar to acquiring property or high-value vehicles. However, as technology evolves and becomes more integrated into the manufacturing sector, we predict a shift in how manufacturers approach and manage these investments.

Prioritizing ROI Over Initial Costs

The focus on the price tag of custom machinery — often reaching into the six or seven figures — is a given during the negotiation phase. Yet, we’re on the cusp of a paradigm shift where the emphasis will increasingly lean towards achieving a swifter Return on Investment (ROI). The smart financial strategy will soon prioritize a higher initial outlay if it means accelerating the ROI timeline, making the upfront cost a calculated step toward faster financial returns.

Recent projects at DEVELOP have seen those with an initial budget opting for solutions that are 30% pricier but double the ROI speed.

This illustrates a very clear shift. Investing more upfront in automation not only makes financial sense but also fast-tracks returns, proving that quicker ROI is the smart move in a competitive market.

Related Reading: Automation Technology ROI

The Rise of Cobot Rental

Collaborative robots, or “cobots,” designed to operate safely alongside human workers, represent a flexible and dynamic component of future robotic technology in manufacturing. While purchasing a cobot as part of a custom automation solution demands significant capital, the concept of cobot rental for simpler tasks is gaining traction.

This model offers manufacturers the flexibility of integrating advanced robotics into their processes on a subscription basis, reducing upfront costs and maintenance responsibilities.

Embracing Agnostic Technology for Cost Savings

The early days of robotic integration were often characterized by reliance on proprietary systems, which led to manufacturers feeling locked into specific brands or technologies. This perception is changing as more integrators adopt a technology-agnostic approach, choosing parts and software based on a balance of cost-effectiveness and quality rather than brand loyalty.

This trend towards diversified, open-market sourcing is expected to drive down costs and increase flexibility in sourcing components.

Broadening Access Through Innovation

Recent advancements in technology, such as the wider availability of 3D printing, have lowered the barrier to entry for precision CNC machinists, job shops, and innovators. This democratization of technology is paralleled in the automation sector, where lower-cost components and integration options are now accessible to smaller players.

This wave of innovation isn’t only making technology more accessible but also building a more competitive environment that encourages the creation of cost-effective, custom solutions.

Improved DEI through Robotic Advancements in Manufacturing

When we look at the future of robotics in manufacturing, it’s imperative to recognize the potential of these technologies to transcend mere productivity gains and act as catalysts for diversity, equity, and inclusion (DEI). Robotics and custom machinery, by their nature, operate without the biases that can influence human behavior, presenting a unique opportunity to level the playing field across the manufacturing sector.

- Democratizing Competition: Robotic technology is a game-changer for small startups, allowing them to match the production capabilities of larger companies. This shift encourages innovation, brings diverse perspectives to the industry, and enriches the market as a whole.

Challenging Traditional Business Values

In reimagining the future of robotics in manufacturing, it’s clear that the potential extends beyond operational efficiency. Through thoughtful integration and innovative design, robotics can play a pivotal role in advancing DEI while challenging outdated business ideologies. This progression towards a more inclusive manufacturing industry shows the transformative power of robotic technology in building a future where everyone has the opportunity to thrive.

The Challenges of Robotic Manufacturing’s Future

As the future of robotics in manufacturing unfolds, it brings with it not just innovations but also challenges. The march towards more advanced integration of robotics into manufacturing processes is inevitable, yet it’s accompanied by potential pitfalls that stakeholders must be prepared to tackle.

The Influx of Opportunists

The rapid expansion of automation within the manufacturing industry has attracted a wide range of entrants eager to capitalize on this trend. However, this surge can lead to a crowded field where not all players are equally prepared or capable.

The risk lies in identifying partners who not only promise but can deliver projects with a focus on meaningful ROI, engineering excellence, and the avoidance of scope creep. The challenge for first-time automation adopters is discerning which integrators bring the requisite engineering discipline and business acumen to truly add value.

Related Reading: Choosing the Right Automation Partner

AI: The Promise and the Distraction

The allure of Artificial Intelligence (AI) is undeniable, with tools like ChatGPT demonstrating remarkable capabilities in generating content and software creating intricate designs from simple prompts. However, the application of AI in manufacturing, while promising for data analysis and operational monitoring, is no substitute for the nuanced, expert-driven engineering processes required to build and integrate robotic systems.

The Pitfalls of Rushing Automation

The excitement around automation’s potential benefits can sometimes lead to hasty decisions and unrealistic expectations regarding project timelines. Effective automation projects, especially those involving complex robotic systems, require careful planning, development, and integration, processes that inherently take time.

The temptation to expedite these processes, driven by the promise of quick returns, can lead to underdeveloped systems, inadequate testing, and ultimately, failed projects that don’t deliver the anticipated ROI or, worse, become costly lessons in haste.

The path forward in the future of robotics in manufacturing is filled with promise but also cautionary tales. By acknowledging these potential pitfalls, businesses can better position themselves to harness the transformative power of robotic technology in a way that’s both strategic and sustainable, ensuring that investments in automation deliver on their immense potential.

Related Reading: Choosing Your First Automation Project

Seizing the Future of Robotics in Manufacturing

As we stand at the threshold of a new era in manufacturing, driven by advancements in robotic technology, it’s clear that the journey towards automation isn’t just a path to efficiency and innovation but a leap into the future of industry itself. The evolution of robotics in manufacturing is transforming the sector, offering unprecedented opportunities for growth, sustainability, and inclusivity.

Of course, adopting automation requires expertise, foresight, and a strategic partner who can guide you through the complexities and potentials of automation.

The future is coming with the promise of robotic technology revolutionizing manufacturing processes, making now the time to consider how you can integrate these advancements into your operations.

With DEVELOP’s expertise in custom automation and robotics, you’re not just preparing for the future, you’re shaping it. Whether you’re looking to enhance efficiency, tackle the challenges of DEI, or understand the economic implications of robotic integration, DEVELOP stands ready to guide you through every step of the process.

Imagine your manufacturing operations transformed by a bespoke robotic system designed with precision to meet your specific needs, not just for today but for the years ahead. DEVELOP’s commitment to innovation, quality, and sustainability means investing in a solution that’s not just cutting-edge but also tailored to last well into the future.

Don’t let the future pass you by. Whether you’re at the planning stage, ready to begin your robotics project, or looking to understand how automation can revolutionize your operations, DEVELOP is here to help.

Tell us more about your project, schedule a virtual meeting, or call (262)-622-6104 to discover how we can build a robotic or automated system that will carry your manufacturing processes into the future and beyond.

With DEVELOP, the future isn’t just something to prepare for — it’s something you can shape, today.

About the Author:

Sean McKittrick, as Project Program Coordinator at DEVELOP LLC, brings a multifaceted background from Knox College. McKittrick’s first year at DEVELOP LLC has been marked by significant team growth and zero turnover, showcasing his ability to build a collaborative and effective work environment. His experience spans quality management in healthcare software to managing production for a million pounds of material monthly, highlighting his diverse expertise in project coordination and manufacturing excellence.