Semi-Custom Linear Transfer Machines

Linear transfer machines and extrusion processing machines sequence parts through a series of dedicated high-speed manufacturing operations, ensuring precision and efficiency. By leveraging our family of modules, we are able to quickly and efficiently construct your extrusion processing machine. This modular approach not only speeds up the manufacturing process but also allows for unparalleled customization, ensuring that your machine is perfectly suited to your specific production requirements.

Supported Part Sizes and Materials

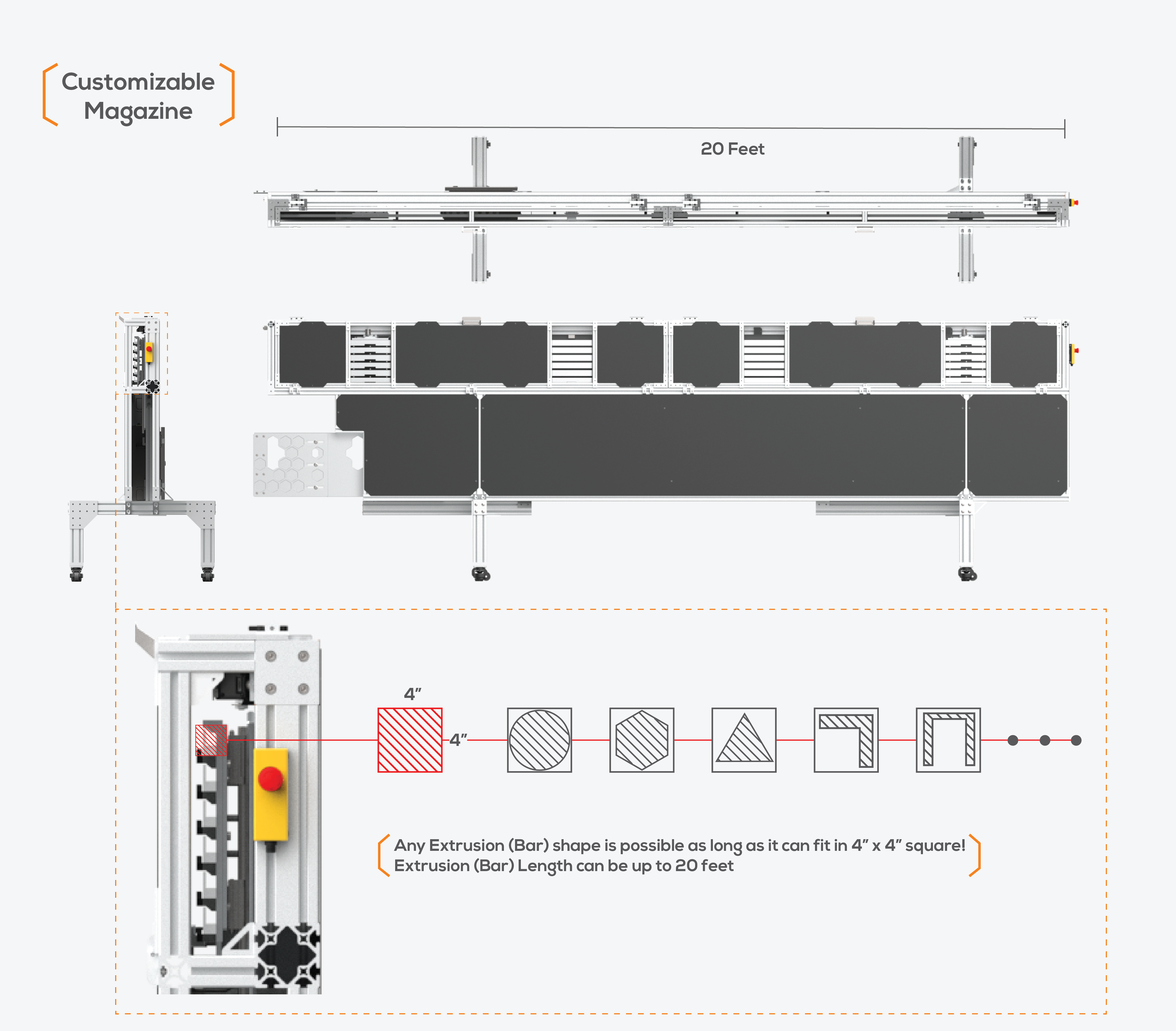

We can accommodate plate, bar, and extrusion material processing with a maximum raw stock size of 4″ x 4″ x up to 20′.

We specialize in the following materials:

- Nonferrous metals: Aluminum, Copper, and Brass alloys.

- Plastics: Polypropylene (PP), Polycarbonate (PC), Acetal (POM), and Acrylics (PMMA).

Modular HMI

We have developed a modular Human-Machine Interface (HMI) with semi-customizable features that we tailor to your needs.

- Real-time job status updates

- Adaptable modules

- Configurable operator security permissions

- Seamless integration into your workflow

- Accelerated onboarding and training process for new operators

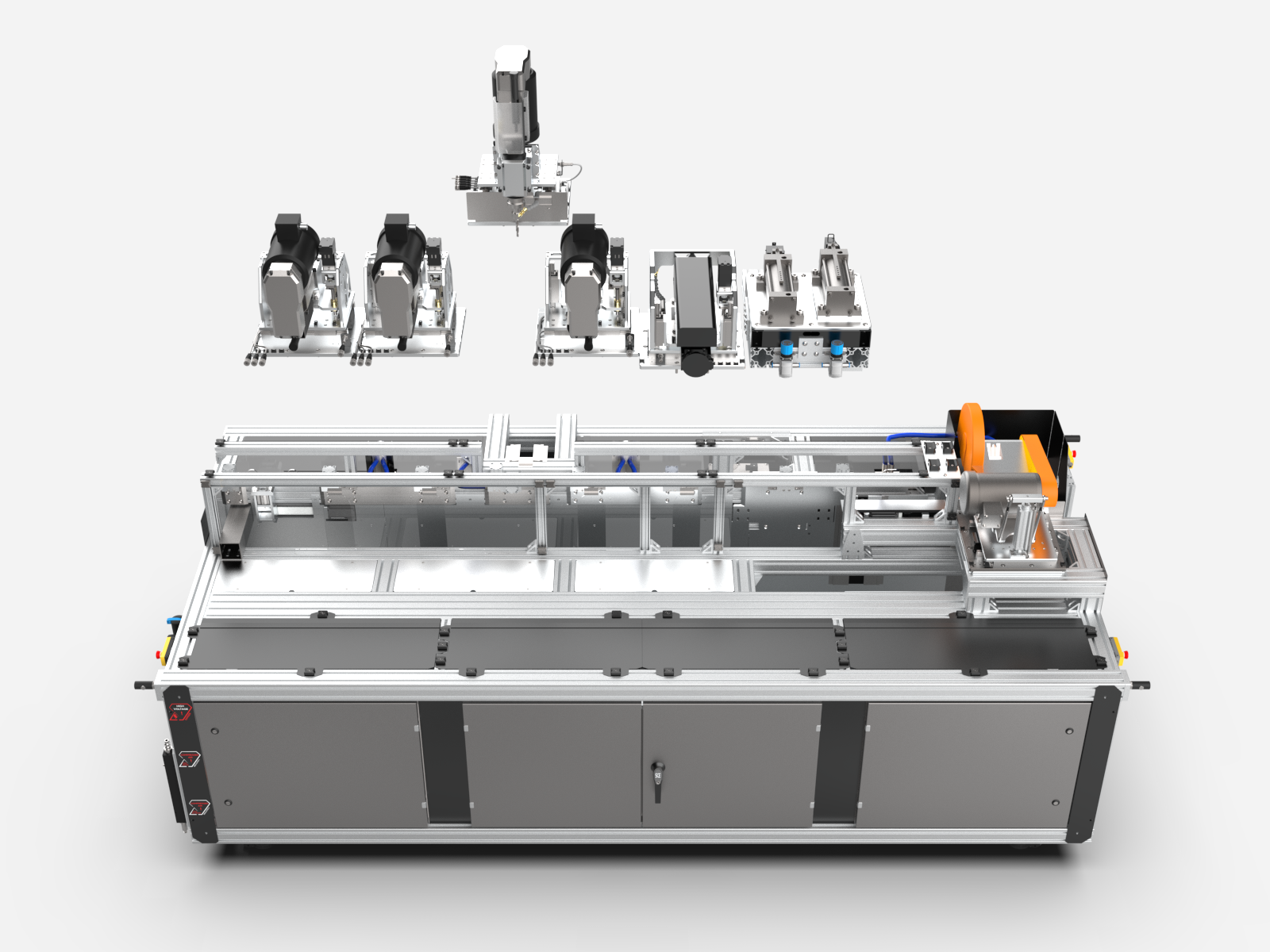

Modular Design

We can construct Semi-Custom linear transfer automation or extrusion processing machines with greater speed, efficiency, and precision by utilizing our extensive library of modular systems. This approach not only accelerates the manufacturing process but also significantly reduces the time it takes for you to begin realizing a return on your investment, compared to the lengthy timelines often associated with fully custom machines.

Configured Modules to build your Linear Transfer Machine Faster

Vertical & Horizontal Drills

For projects requiring precise drilling or chamfering, DEVELOP offers an extensive range of pre-configured modules designed to meet your specific needs regardless of the hole’s size and orientation. These modules are expertly engineered to facilitate both vertical and horizontal drilling.

Vertical & Horizontal Tapping

Dedicated tapping modules are designed to maximize the speed at which you thread holes in your linear transfer machine. These modules can be configured for both vertical and horizontal tapping.

Sawing

Sawing involves precise cutting and dropping parts, which can vary widely depending on the specific application. Our saws are designed with modularity in mind, allowing for quick modifications to adapt to your unique work holding requirements.

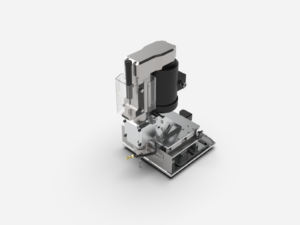

Vertical and Horizontal Milling

Our milling modules are designed to accommodate a limited size range of parts. Built with rigidity in mind, these modules are perfectly suited for executing both simple and complex machining operations. These modules are compatible with tool changers to enhance versatility between different machining tasks.

Work Holding

Indexing and clamping can be part or profile-specific. Our approach leverages a modular design, enabling our team to swiftly create customized solutions to meet each project’s unique requirements.

Magazine

Whether you’re dealing with long extrusions or cut plates, our magazine options are designed to meet your specific needs, ensuring that your linear transfer machine operates at its full potential.

For businesses processing long extrusions, ranging from 8 to 20 feet. We utilize a pushing magazine.

For operations involving cut plates, we utilize a top-picking magazine.

Maintenance & Support:

With our built-in remote access capabilities, we can directly support your machine and software from our facility. This allows us to increase machine uptime and collect comprehensive data significantly. This data collection facilitates real-time machine performance monitoring and is accessible to anyone who needs it. This means you can always stay informed about how your equipment is functioning.

Why a Modular Linear Transfer Machine: Unbeatable Advantages

We build linear transfer and extrusion processing machines because they support low-mix high-volume parts better than any other automated solution. They offer:

Speed

- Turns raw extruded bar or plate materials into finished products with speeds that far outstrip robotic arms or assembly lines.

- Unmatched consistency, quality, and turnkey efficiency with machine quickness.

- Each module acts as its own stop on the assembly line.

- Using sequential processing, every individual manufacturing action happens at the same time, limiting your cycle speed to the longest cycle time of your part, rather than cumulative assembly generation stages.

Scalability

Modularity is built into the design of the machine. DEVELOP LLC creates the custom specifications required by your project and supports swift creation of your linear transfer machine with a deep library of module designs. We plan for:

- The addition of more modules.

- The extension of the extrusion line.

- The function-ready addition of further modular linear transfer machines as you grow.

Return on Investment

Any integrator can use ROI to justify the costs, but we educate on how the demonstrably better throughput, lower floor plan footprint, and increased production capacity open you to opportunities for increased sales, company growth, and worker advancement opportunities.

Workforce Support

Professionally integrated modular linear transfer machines and extrusion processing machines translate to a better work environment, safer work conditions, and training opportunities into workforce retention and job satisfaction.

Education & Training

We pride ourselves on our reputation for educating beyond our competitors. We teach for machine mastery, operational perfection, and the ability to self-service and self-train.

The DEVELOP LLC Difference

At DEVELOP LLC, we commit ourselves to understand your business, understanding your targets, and translating those precision requirements into custom automated solutions. Our custom integrations cannot be beaten for low-mix high-volume manufacturing needs. Stop considering which machine, which robot, and which technology to select, and start demanding what you can imagine. Let our project managers, software engineers, and manufacturing experts guide you to the next level of your production with our single-source guarantee.

Contact us today to schedule your automation assessment and learn how an integrated modular linear transfer machine can bring you to a higher level of competition.