At DEVELOP LLC, we want you to be wary of the claim that all manufacturing processes can be automated from beginning to end. Maybe you’ve heard a pitch like this:

- “It’s not impossible to automate 100% of your assembly, packaging, and shipping for every stock keeping unit (SKU) in your inventory catalogue all at once!”

- “Theoretically, one machine can handle all of your problems!”

- “We can build a machine that can finish dozens of sizes at the same time!

The insidious thing about these statements is that there is some truth to the idea that given limitless time, money, and effort, a custom automated machine could robotically automate your entire production. Everyone craves perfection, and when a custom automated machine can cost six to seven figures and take months to years to complete, it’s easy for first time automation customers to get lured in by promises of a machine that is agnostic to micromachined detail, variable sizes, multiple material feeds, and can manage every part of your manufacturing processes.

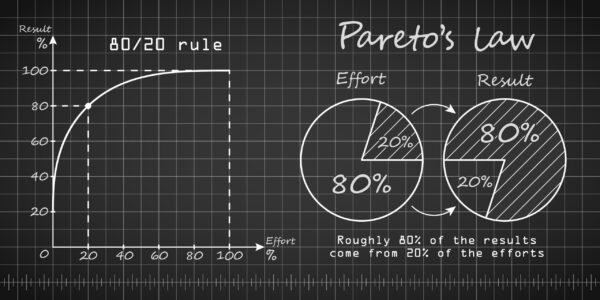

Finding your 80/20

We advocate strongly for the 80/20 approach. Sometimes also called the Pareto Principle after 20th century Italian economist Vilfredo Pareto, 80/20 is the consistent observation that 80% of the profits, sales, and market share for the average business is often generated by 20% of the customers, products, and manufacturing SKUs. Narrowing the scope of an automation integration towards the most profitable targets, the most growth potential, or the bottlenecks that are holding back scaling your business is the key to the fastest return on investment, the quickest development cycle, and the lowest project risks. A professional integrator will know how to measure your annual volumes against engineering and programming lift. We want to show you why you should lean into 80/20 rather than pursue 100%.

80/20 Aims for the Fastest Return on Investment (ROI)

If you have multiple product lines, it’s pretty easy to tell which ones are the strong performers. Strong sales, good reviews, and measurable demand increases all tell you which products need to scale. Similarly, you might have a series of products that only satisfy obligations, struggle to break even from pre-investment, or cater to a limited audience of customers that just don’t have the potential for growth. Just because a machine could be built that could handle the assembly of both your low performance products and the product that customers are fighting to buy doesn’t mean you should. Every unique function, additional SKU, and variable tolerance is going to have an exponential impact on your cost, not an additive effect. Choosing to add functions to a machine that won’t transition into exponential gains is a misappropriation of resources. Limiting your investment capital and machine design into the products and SKUs that will net that 80% profit through targeting that 20% will meet that exponential growth.

Average automated machine life is 15-20 years. If your machine outstrips your capital investment in two years rather than ten, that’s money to reinvest, pursue lucrative opportunities, and research new deals and products. A responsible integrator will guide you towards the volumes that will net you the biggest gains.

80/20 Shortens the Development Time

ROI takes months or years, but the second your new machine is bolted to the floor, you are on a completely new level of competition. Every minute that the machine or robot is not making your products is a minute you can’t use to hire employees to address the additional sales, pursue sales to match your increased capacity, or redirect your energy toward research and development. We’ve talked about how each additional function of your machine will exponentially escalate your costs. More functions means an exponential impact on your machine delivery timelines as well.

Every new function needs design, software programming, training materials, part scoping, firmware, logistics, and extensive testing. It’s a no brainer that scoping the placement, targets, and volumes of your machine for multiple functions, sizes, and tolerances takes longer. Even the most off the shelf turnkey solution needs some amount of custom design. The more components in your machine specs, the longer your lead times from suppliers. And any hiccups, errors, or challenges in the integration process has a time-consuming domino effect of adjustment to every SKU on the machine. The compounding affect of adding an additional SKU to the design is not linear, it’s logarithmic. Adding a low performing SKU to the design increases the cost and timeframe exponentially. Directing the design towards 80/20 solutions directs you to the fastest completion of your machine. A disciplined integrator weighs the requests for additional functions and offers that some of the requests could be another project.

80/20 Mitigates Risk

Imagine this scenario: Your machine that does everything breaks down. What happens?

Every process in your manufacturing grinds to a halt. Maintenance crews have to stop and check the dozens of processes on your machine to narrow down what went wrong.

While the maintenance crew checks the machine, you have to take a look at the schedule and decide which freight pick ups need to be cancelled or rescheduled. Your production manager questions whether you need to start calling customers now to let them know order delivery will be late, or if you want to risk waiting to see how bad the damage is first.

Crew are sent home without getting their hours or you have to pay wages to idle workers while they wait.

If you are lucky, your maintenance team has the parts and know-how to get your machine back up and running in a few hours or a day. If you are missing parts or need to contact your integrator, you could be looking at days or weeks. Since the replacement parts needed have to work with a high number of different SKU’s, the premiums on paying for rarer parts and rarer knowledge skyrocket. Your job now becomes convincing customers to accept delays and prevent cancelled orders.

Imagine how frustrating this scenario would be if the machine was shut down by your lowest performing product. An assembly line thrives on commitment to consistency, quality, accuracy, and efficiency. The more complicated the challenge, the more likely you will have to dedicate energy, money, and time to managing the crisis. Focusing your custom automated machine project on 80/20 mitigates risk in every category.

Compartmentalization

An 80/20 machine allows you to generate the low mix high volume production you need for your customers without halting your production rate during maintenance. Your other production lines can still run while your machine is maintained. With the money you saved focusing on 80/20, you can more easily afford multiple machines of the same type that can pick up the production slack while necessary maintenance is performed.

Market Shifts

What happens if one of your low performing products becomes a no performing product? In an everything machine, you have a vestigial process on your machine that only serves as a failure mode. An 80/20 machine that manages your highest performing products has a longer forecast for success, an easier to anticipate decline, and better margins for brand insulation. The lower capital expenditure cost for the 80/20 machine makes it easier to adapt to a new machine project while maintaining the other machine.

Change orders

Ideally, your machine design shouldn’t change in the prototyping phase. Any change order has a disruptive domino effect in the vertical planning steps for a custom automated machine or robotic solution. Changing the design on a more focused 80/20 machine will require much less labor, engineering lift, scope shifting, and cost.

Replacement

Every machine has shelf life. Replacing an 80/20 machine will have a lighter impact on cost, training, and timelines. The lower footprint can also leave room in the machine design for changes in the marketplace, a need to pivot to different products, innovations, or changes in demand.

At DEVELOP LLC, we pride ourselves on the ability to aim for the 80/20 targets that can support your growth while maintaining the swiftest course for return on investment. Tell us more about your project, schedule a virtual meeting, or call (262)-622-6104 to learn more about how we can help you automate your business responsibly.

Authors:

Sean McKittrick and Matt Moseman