Investing in custom automation solutions can be transformative but naturally involves significant cost. It’s crucial to ask if the potential automation ROI will justify the expense. When a custom automated machine integration costs six to seven figures and takes months or years, the question becomes less about how to do it and more about whether it can be done within a practical budget.

Any level of automation capital investment requires long-term expectations, the involvement of owners and CEOs, and, in most cases, business loans. That kind of risk needs to be justified.

Let’s explore how to calculate your automation investment returns and make data-driven decisions.

Don’t Start with a Quote — Focus On Automation Investment Impact

Calculating automation ROI shouldn’t start with a focus on quotes. Without understanding your specific goals, production metrics, and overall financial situation, any quote is just a guess. To maximize your automation investment, prioritize ROI analysis first.

Requesting an NDA (Non-Disclosure Agreement) early on protects your sensitive data while laying the groundwork for a detailed ROI calculation. A responsible automation integrator will have a mutual NDA ready, demonstrating their commitment to transparency and partnership.

Related Reading: Comprehensive Guide to Industrial Automation

Calculating Your Automation Investment

An ideal automation ROI calculation goes beyond simple numbers. It should provide a clear picture of how the investment aligns with your business goals and fuels long-term growth. Here’s what to look for:

- Customization: The ROI calculation should reflect the unique financial details of your business, factoring in your current production costs and operational inefficiencies. A cookie-cutter ROI won’t capture the nuances of your specific situation.

- Cost-Comparison: It should outline the potential savings of an automated solution compared to your current processes. This includes not just direct labor costs but also potential reductions in scrap rates, rework requirements, and energy consumption.

- Realistic Timeline: The ROI provides a reasonable timeframe for the automation investment to start generating returns. Be wary of overly optimistic projections, but also factor in increased efficiency and scalability that can accelerate your payback period.

- Growth Potential: A strong ROI considers the opportunities for expansion and increased revenue resulting from automation. This might involve increased production capacity to meet growing demand or the ability to take on new product lines that were previously impossible due to manual limitations. It should also explore the potential for labor redeployment, freeing up skilled workers for higher-value tasks and fostering innovation.

Most integrators will have a demo, a web form, or a downloadable calculator to start customers with some research on how attainable a large project can be based on an estimated budget.

We have our own ROI calculator here; feel free to try it out. Try out the reverse function to calculate an automation budget.

Related Reading: How You Should (and Shouldn’t) Calculate Your Return

on Investment with Your Integrator

Why ROI Isn’t Your Full Business Plan

It’s crucial to understand that automation ROI, while essential, isn’t a comprehensive business plan. ROI calculations focus on financial figures, estimated savings, and the potential return on your automation investment. Their primary purpose is to justify the project’s feasibility and demonstrate its potential value.

Confusing ROI with a detailed business plan or a rigid contract can significantly limit your vision. No one should ever treat the ROI calculations the way you would treat gated stage expectations in a Statement of Work Contract. Here are some of the key reasons why.

ROI Predicts Feasibility, Not Your Growth Trajectory

Even the most detailed ROI calculations compare your current production to an estimated future state. ROI can justify automation investment, but it cannot fully predict how you’ll leverage these new capabilities. At the most basic level, here’s what your automation ROI calculations should cover:

- How much you spend

- How much more cost-effective your production will be

- Theoretically, how long it would take for the more cost-effective production to make back that money.

But the way you approach the ROI of automation can be further fine-tuned by considering answers to the following:

- Increased production capacity unlocks space for expansion as your production floor has more real estate to work with. Can you develop new product lines or take on higher-volume orders? Rededicate that space for more production opportunities that generate revenue.

- When your new machine improves the work environment by taking on those dirty, dangerous, ergonomically challenging, high-turnover positions, you’ll have less turnover. Improved working conditions reduce turnover and associated recruitment, training, and onboarding expenses. How will you reinvest these savings — workforce development, R&D, or new revenue streams?

- When you make more products for less cost without sacrificing quality, you can boost customer satisfaction and attract new sales. How will you capitalize on this?

Related Reading: Getting Your Workforce on Board for Change

Automation ROI Is a Starting Point, Not the Finish Line

An ideal automation project considers ROI as the justification to move forward, not the sole measure of success. The true value of automation comes as you exploit those advantages: expansion, workforce development, and revenue growth. These benefits begin as soon as the machine is integrated, delivering returns beyond what any ROI calculator can predict.

These three factors represent the true power of custom automation, extending far beyond what an ROI calculator can predict.

To fully realize these benefits, you need a vision to transform your business with your new automated solution. These advantages start the moment your custom machine becomes operational, not years down the road, as you wait for a calculated ROI.

Accept the ROI as your justification, then focus your energy on maximizing these strategic opportunities — that’s how you’ll drive true automation success and achieve a significant impact on your bottom line.

Related Reading: Questions to Ask When Choosing an Integrator

for Automating Your Manufacturing

Automation ROI — Thinking beyond the Initial Calculation

Your costs will inevitably change in the coming years. With automation, you’ll need to strategically redeploy your workforce to capitalize on the increased production capacity. It’s crucial to plan for the next automation improvement or process enhancement to maintain your competitive edge.

Focusing solely on a rigid ROI can hinder this forward-thinking mindset. Instead, view your automation ROI as a realistic estimate that allows for flexibility in a changing market. Remember, manufacturers who are hesitant due to the initial figures often regret their indecision when inflation outpaces the cost of the project itself.

Viewing ROI as a dynamic estimate encourages proactive decision-making and long-term success.

Related Reading: Never Automate Without a Single Source Guarantee

Streamlined Automation ROI: Focus On the Big Picture

There’s nothing wrong with an overly intricate automation technology ROI, but there’s nothing right with it, either. Your integrator can spend hours drilling down to per-minute power requirements, the per diem cost of latex gloves, cardboard costs, and any number of contributing factors that could impact the cost of your manufacturing.

But, obsessing over those details is a distraction from the opportunities and the attainability goal of automation technology ROI. We like to keep it simple:

- Project Estimate: Get a ballpark figure for the total integration cost, including design and engineering hours. This should be based on your desired cycle times, SKUs, and overall project timeline.

- Shift Comparison: Analyze how automation will affect your shift requirements, comparing the manual process to the enhanced automated solution.

- Employee Allocation: Determine how many workers are needed per shift, both for manual tasks and operating the automated machinery. Keep in mind, automation often allows employees to multitask or focus on higher-value activities.

- Total Employee Compensation: Calculate the full cost of an employee, including salary, benefits, insurance, etc. This helps gauge the true labor savings.

- Significant Cost Savings: Think beyond minor expenses. An experienced integrator will identify major savings opportunities in areas like reduced waste, improved tooling efficiency, and minimized rework. These savings significantly impact your bottom line.

Related Reading: Choosing Your First Automation Project

Automation Technology ROI Scatterplot: Practical Application

Automation technology ROI should be treated as a useful tool at the beginning of the project. Automation ROI calculation is necessary, simple, and important to justify the adoption of the project.

However, once you abandon the notion that automation technology ROI is a business plan or that ROI is the actual invoice amount of the project, the practical application of quick, professional ROI calculations allows you to consider multiple machines.

We take the information we gather during an automation assessment and refine the opportunities for automation investment in your entire production into an ROI scatterplot. High-level figures for your automation ROI calculation allow us to scope multiple projects, multiple automation technology ROIs, and multiple levels of risk.

High-level budgets narrow in on the real opportunities to add dollars to your bottom line. We present these options with breakdowns of why the projects cost more or less, which take more or less time, and which projects mitigate the most risk.

- Focus on Solutions, Not Specific Machines: Prioritize finding the best solution to achieve your desired outcome, even if that means being open to different machine options. A solutions-based approach maximizes your potential for a profitable automation investment.

- Prioritize a Faster ROI: While the upfront cost is important, don’t let it overshadow the potential for a quicker ROI. Strategic investments can sometimes result in substantially faster returns, significantly impacting your bottom line.

- Manage Automation Risk Carefully: Remember, even seemingly simple automation solutions require custom engineering tailored to your specific needs. Adding complexity increases the risk of unexpected costs or delays. Choose an integrator who thoroughly assesses the viability of a solution before committing to precise specifications.

Related Reading: Overcoming Engineering Challenges in Automation

Assessments for Automation Technology ROI

Automation ROI calculators and data tracking estimates are effective tools to get started with your own industrial automation project, but a professional industrial automation integrator is key to leveraging the highest accuracy and most value from your automation investment calculation.

- Explore Diverse Automation Opportunities: Assess your entire facility to identify multiple areas where automation could provide significant ROI. Compare different projects, balancing investment cost, risk, lead time, and potential return.

- Ensure Solution Design Expertise: Choose an integrator whose team includes software experts, electrical and mechanical engineers, and custom machine specialists. This diverse expertise ensures your theoretical automation ideas are translated into viable, high-performance solutions.

- Prioritize Results, Not Just Features: Focus on your desired outcomes related to output, quality, and consistency. A skilled integrator will transform these goals into the specific technical requirements and design for your automated solution.

- Partner for Reliable ROI Guidance: Work with an automation integrator who demonstrates a deep understanding of ROI. They should be able to confidently address your questions, help you assess risks, and guide you toward informed investment decisions.

Unlock the True Value of Automation

You’ve looked into the power of automation ROI — a strategic roadmap to optimize your production lines, empower your workforce, and unlock significant cost savings. But translating those theoretical calculations into real-world results requires more than just a spreadsheet. Now’s the time to bridge the gap between possibility and profitability.

Partnering with a professional automation integrator equips you with the engineering expertise and results-oriented approach you need to maximize the return on your investment. Our team of skilled professionals analyzes your unique production needs, identifies areas ripe for automation, and explores a range of potential solutions. We don’t just deliver cookie-cutter designs; we design custom automation solutions meticulously tailored to achieve your specific goals.

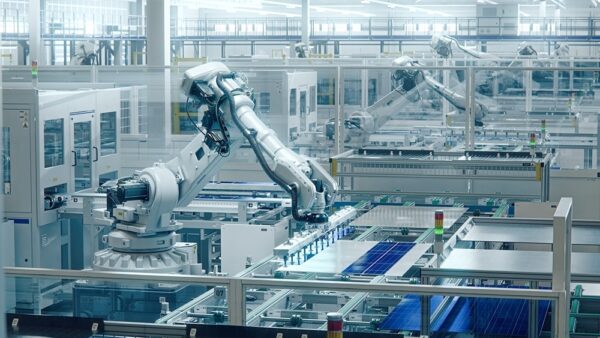

Picture your production floor transformed by intelligent automation. Envision streamlined processes that reduce waste and errors while empowering your human workforce to focus on higher-value tasks. A skilled integrator translates your vision into a reality, meticulously designing every aspect of the solution to deliver exceptional quality, consistent output, and significant cost reductions.

Success begins with a conversation. Tell us about your project, schedule a virtual meeting, or call (262)-622-6104 to discuss your goals with a professional. Together, we’ll develop a detailed automation ROI analysis and explore the custom solutions that will drive your business forward.

About the Author:

Sean McKittrick, as Project Program Coordinator at DEVELOP LLC, brings a multifaceted background from Knox College. McKittrick’s first year at DEVELOP LLC has been marked by significant team growth and zero turnover, showcasing his ability to build a collaborative and effective work environment. His experience spans quality management in healthcare software to managing production for a million pounds of material monthly, highlighting his diverse expertise in project coordination and manufacturing excellence.