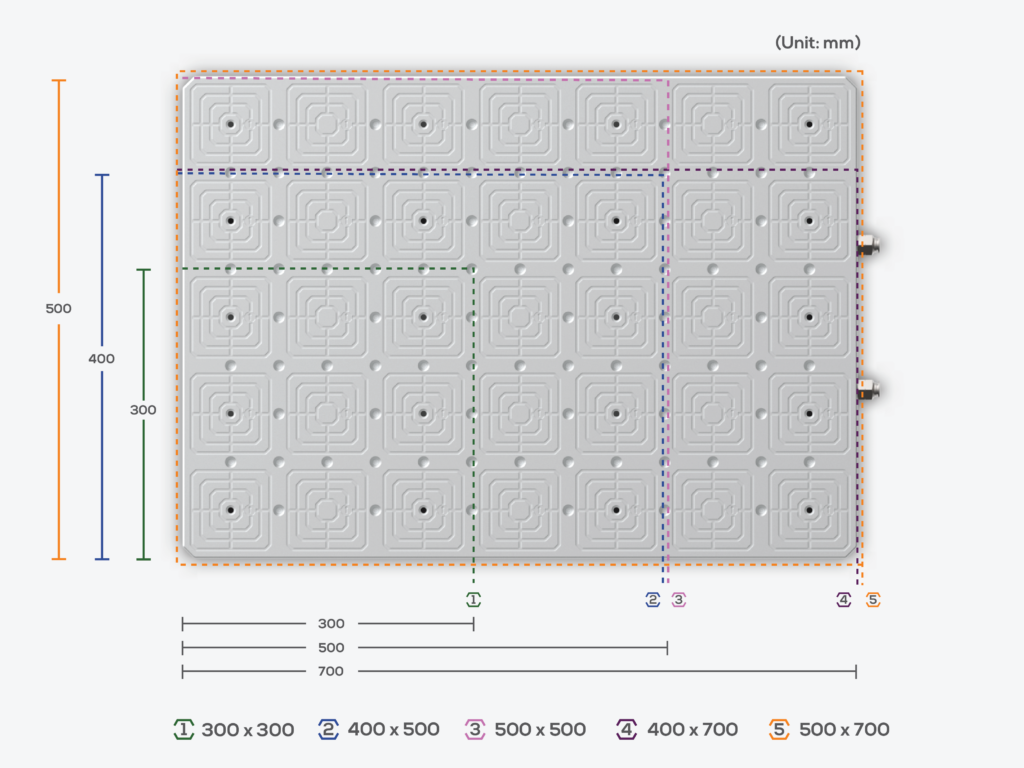

Vacuum Fixture Plates – General Sizes

$1,475.00 – $5,270.00

Our Vacuum Fixture Plates and accessories combine the staying power of conventional vacuum chucks with the versatility of a fixture plate system. These workholding solutions facilitate quick part change-outs, all with a simple, low-profile setup. Perfect for low-volume, high-mix manufacturing.

Made-to-order configurations upon request

$1,475.00 – $5,270.00

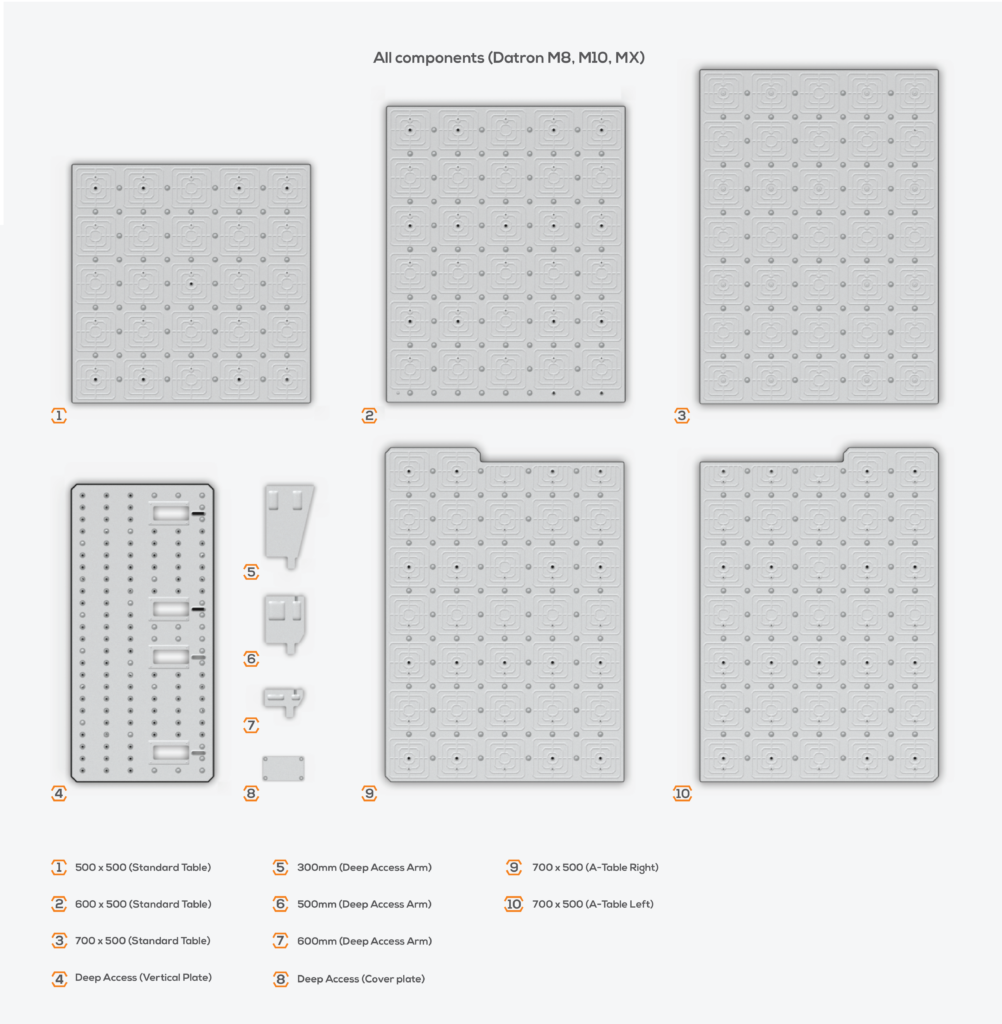

Specialized vacuum fixture plate products and accessories customized for Datron CNC machining and workholding.

$1,250.00 – $1,500.00

$8,350.00 – $10,145.00

$2,450.00 – $3,645.00

$2,950.00 – $10,145.00

Our industrial designers and mechanical engineers work together to deliver efficient, functional, cost-effective, and compliant end products that work as intended.

To get started, contact us today.