The plastics industry is undergoing a transformative shift, driven by demands for increased efficiency, precision, sustainability, and the ability to meet growing customer demands for product sub-assemblies. In this era of plastic manufacturing automation, staying competitive requires embracing advanced automation technologies for plastics.

Whether you need custom machines for injection molding machines – including post processing – or extrusion automation for drilling, milling, and cutting, DEVELOP has you covered. We’re also your trusted partner for integrating bigger, smarter manufacturing solutions across your plastics facility.

Not sure if automation for your facility is the right choice? Take a few minutes to complete our free Automation Assessment questionnaire, and get immediate insights on whether adopting plastics automation will provide a reliable return on your investment.

Robotic Applications for the Plastics Industry

Robotic automation is revolutionizing the plastics industry, enabling new levels of efficiency, precision, and cost-effectiveness. By integrating industrial automation for plastics solutions into various stages of production, manufacturers can unlock new possibilities for growth and innovation.

From plastic automation equipment that accelerates material handling and assembly to robotic systems that optimize inspection, packaging, and palletizing, the applications are vast and diverse. This transformative technology is not only reshaping manufacturing processes but also allowing businesses to adapt to evolving market demands and maintain a competitive edge.

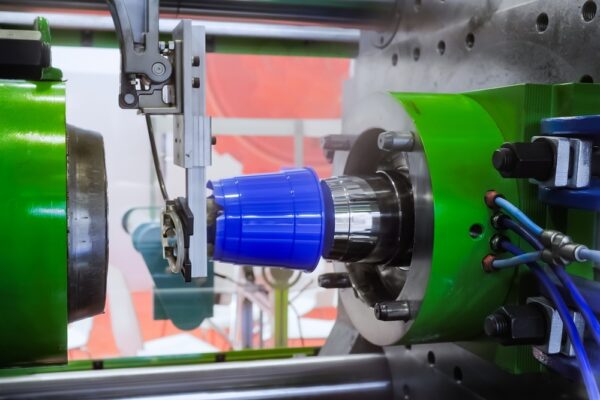

Injection Molding Automation

A core process in plastics manufacturing, automating injection molding can significantly enhance its efficiency and precision.

Robotic Automation for Injection Molding Machines

Post-injection molding machine robots seamlessly integrate with existing injection molding machines to automate repetitive and labor-intensive tasks. These robots can efficiently handle part removal, insert loading, and other post-molding operations, significantly reducing cycle times and minimizing the risk of human error. By automating these processes, manufacturers can increase throughput, improve product consistency, and optimize overall efficiency in their injection molding operations.

Integrating robotic automation into injection molding processes not only enhances productivity but also allows operators to focus on more complex tasks, improving job satisfaction and overall operational effectiveness.

Automated Post-Injection Molding Processes

Post-injection molding processes cover a variety of tasks, from part removal, de-gating, and trimming to quality control and packaging. Integrating automation in plastic processing can significantly enhance efficiency, reduce labor costs, and ensure consistent product quality.

Applying plastic automation equipment, such as robotic systems, can integrate into the post-injection molding workflow, taking over repetitive and labor-intensive tasks. For example, robotic arms equipped with specialized end-effectors can efficiently remove molded parts from the machine, eliminating the need for manual intervention. This not only reduces cycle times but also minimizes the risk of damage to parts caused by human error..

Ready to optimize your material flow and eliminate bottlenecks? Find out more about our virtual and on-site Automation Assessments, where our experts will dig into the specifics of your operation and determine if and where automation can revolutionize your material handling processes.

Assembly and Finishing Automation

The assembly and finishing stages are where your plastic products take their final form. Automation ensures precision, consistency, and efficiency in these critical processes.

Component Assembly

By automating repetitive and labor-intensive assembly operations, we help you reduce errors, improve product quality, and free your workforce to focus on more complex tasks.

Custom robotic assembly systems excel at intricate component assembly tasks, ensuring precise alignment, secure fastening, and consistent quality.

Finishing Operations

From de-gating, trimming and deburring to polishing and surface treatment, we can build a machine or robotic automation solution to accelerate finishing operations, ensuring that your plastic products meet the highest standards of quality and aesthetics. By automating these processes, we help you achieve consistent results, reduce rework, and enhance the overall appearance of your products.

Ready to boost your assembly and finishing processes? Learn how you should (and shouldn’t) calculate your return on investment with your integrator. DEVELOP’s expertise can help you understand the ROI calculation process and ensure you consider all the factors that contribute to a successful automation investment.

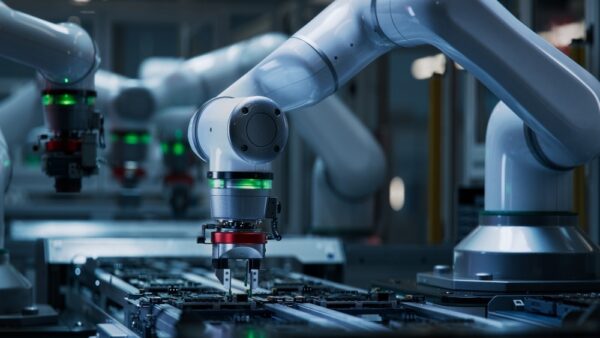

Quality Control and Inspection Automation

Maintaining stringent quality control is essential in the plastics industry. Our automation solutions ensure that your products consistently meet or exceed quality standards. Taking advantage of automated quality control in plastic production is easier than you might think.

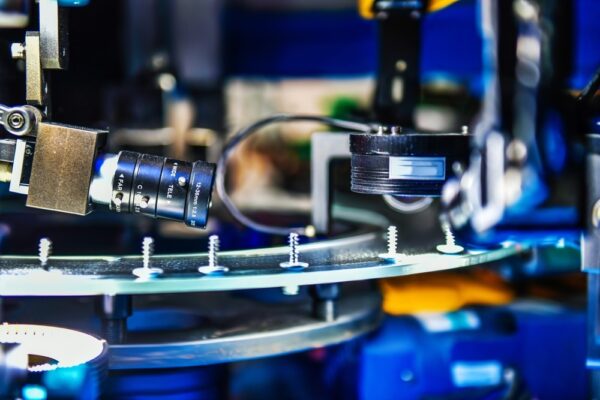

Automated Inspection

Custom automated inspection systems use advanced vision technologies and machine learning to meticulously scrutinize plastic components for defects, inconsistencies, and dimensional variations. By integrating these automated systems into your production line, you can proactively identify and address potential issues in real-time, ensuring that only the highest quality products leave your facility. This not only enhances overall efficiency but also significantly reduces the risk of costly product recalls..

Ready to ensure the highest quality standards for your plastic products? Discover our complete range of Automation Services for the manufacturing sector, designed to seamlessly integrate automated inspection and non-destructive testing into your production line, guaranteeing unparalleled quality control and peace of mind.

Packaging and Palletizing Automation

Efficient packaging and palletizing are essential for improving the logistics and distribution processes of the plastics industry.

Robotic Packaging for Plastics

In the plastics industry, packaging efficiency directly impacts your bottom line. Manual packaging can be slow, error-prone, and costly. Robotic packaging for plastics offers a solution to these challenges by automating the process, ensuring consistent quality and speed, regardless of the variety of product sizes and types.

Implementing plastics manufacturing packaging automation means you not only reduce labor costs but also minimize packaging errors and increase throughput.

Robotic packaging systems can handle a wide range of packaging materials and configurations, from simple bags and boxes to complex custom packaging, ensuring that your products are packaged securely and efficiently, regardless of their dimensions.

This flexibility can significantly improve your overall productivity and reduce your time to market.

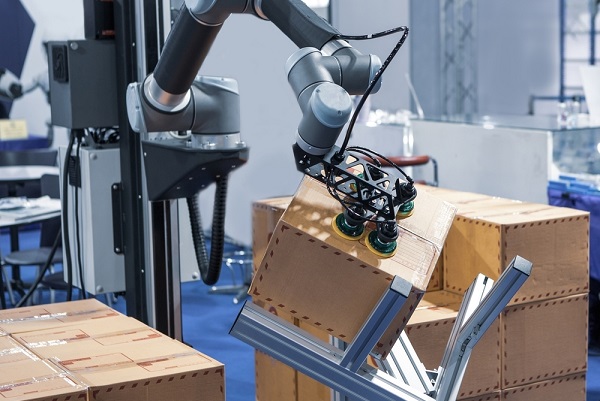

Robotic Palletizing for Plastics

Optimizing warehouse space and ensuring the safe transportation of goods are critical concerns for any plastics manufacturer. Robotic palletizing for plastics not only addresses these concerns but also transforms logistics processes, improving overall efficiency.

By automating palletizing, you reduce the risk of product damage caused by manual handling errors, leading to higher customer satisfaction. Robotic palletizers consistently stack and arrange products in a precise and stable manner, ensuring optimal load configuration for safe transportation. This precision minimizes product losses during transit, protecting your investment and your reputation.

Robotic palletizing systems are highly adaptable, accommodating a wide range of product sizes, shapes, and weights. This versatility allows you to efficiently handle a diverse range of plastic products, maximizing pallet space utilization and cutting shipping costs.

Ready to supercharge your packaging and palletizing operations? Enhance your understanding of the transformative power of automation in logistics. Dive into our Manufacturer’s Guide to Palletizing and Packaging Robots for thought-provoking insights and discover how DEVELOP’s solutions can optimize your end-of-line processes.

Sprue and Runner Removal Automation

In the plastics injection molding process, efficient removal and processing of sprue and runners is essential for minimizing waste and maximizing resource utilization. Automated solutions like high-speed runner removal automation and industrial sprue removal robotics offer a significant advantage in streamlining this process.

Automated Trimming Solutions

Reducing labor costs, improving product consistency, and minimizing material waste are just a few of the benefits manufacturers can achieve by implementing automated trimming systems. These solutions, incorporating advanced high-speed trimming automation and robotic runner removal solutions, use precise robotic manipulation and cutting tools to efficiently remove excess material, sprue, and runners from molded plastic parts.

Industrial trimming automation solutions not only transform the trimming process but also contribute to a more cost-effective and sustainable operation. By incorporating robotic trimming equipment into their workflow, manufacturers can experience a significant reduction in labor costs, a marked improvement in product consistency, and minimized material waste. The advanced technology of automated trimming solutions delivers precise and repeatable results, ensuring high-quality finished products while minimizing waste and resource consumption.

Interested in optimizing your trimming process? It all comes down to ROI. You can get actionable insights with our in-depth look at How to Maximize Automation ROI: A Manufacturer’s Guide and discover how DEVELOP’s solutions can boost your return on investment. Remember, the right automation solutions in the right place pay for themselves by delivering a significant financial payback period.

Extrusion Processing

Extrusion is a versatile process in plastics manufacturing, and automation can significantly enhance its efficiency and precision. We offer comprehensive industrial extrusion automation solutions tailored to the unique demands of extrusion processing automation equipment.

Semi-Custom Linear Transfer Machines

Semi-custom linear transfer machines or extrusion milling machines improve extrusion processing by sequencing parts through dedicated high-speed operations. Using a family of modular systems, we build systems tailored to your production needs, delivering both speed and customization, resulting in accelerated manufacturing and reduced time-to-ROI compared to fully custom machines. Integrated robotic extrusion systems offer material versatility, accommodating plate, bar, and extrusion materials in various sizes and nonferrous metals and plastics, and high-speed operations to ensure precision and efficiency.

This integrated approach to plastics extrusion handling automation can significantly enhance the overall productivity and effectiveness of your extrusion process.

Human-Machine Interface (HMI)

An intuitive Human-Machine Interface (HMI) provides operators with real-time insights into extrusion operations, offering real-time job status updates and customizable features for personalized control.

Drilling and Tapping

Pre-configured modules for precise drilling and tapping operations are transformative. These include vertical and horizontal drilling modules for hole creation and chamfering, as well as vertical and horizontal tapping modules for efficient thread creation.

Sawing and Milling

Modular saws adaptable to various workholding requirements allow for precise cutting and dropping of parts. Rigid milling modules are designed for both simple and complex machining tasks, accommodating a variety of part sizes and materials.

Workholding and Magazines

Customizable indexing and clamping solutions ensure secure part handling throughout the extrusion process. Pushing magazines are available for long extrusions, while top-picking magazines are suitable for cut plates, optimizing material flow and efficiency.

Maintenance and Support

Built-in remote access capabilities allow direct support for the machine and software, ensuring maximum uptime. Comprehensive data collection allows for real-time performance monitoring and valuable insights, accessible to the manufacturing team.

Ready to transform your extrusion processes and achieve unparalleled precision? Choosing the right automation partner is crucial for your success. DEVELOP LLC is a single-source provider, meaning we handle all aspects of your project in-house, ensuring a seamless integration and maximizing your ROI. Our proven experience in the plastics industry speaks for itself.

Thermoforming Automation

Thermoforming is a widely used process for creating plastic packaging, trays, and other products. Automation can transform this process, improving efficiency and consistency.

Sheet Loading

Automated sheet loading systems handle the loading of plastic sheets into thermoforming machines with precision and efficiency, reducing the risk of damage and ensuring consistent production cycles. By automating this task, you improve process efficiency, cut manual labor costs, and minimize material waste.

Part Removal and Stacking

Robotic systems efficiently remove thermoformed parts from the machine and stack them for further processing or packaging. This helps you improve production speed, reduce the risk of part damage, and optimize your overall thermoforming process.

Ready to automate your thermoforming operations and boost your production efficiency? Book your free consultation with DEVELOP’s automation experts today. We’ll discuss your specific needs and demonstrate how our cutting-edge robotic solutions for plastics can revolutionize your thermoforming process.

Blow Molding Automation

Blow molding is a critical process for manufacturing hollow plastic products, and automated quality control in plastic production can significantly improve its efficiency.

Part Handling

Robotic part handling systems streamline the removal of blow-molded parts from the machine, ensuring gentle handling and minimizing the risk of damage. By automating this process, you reduce cycle times, improve throughput, and maintain consistent product quality.

Quality Inspection

Advanced automated quality inspection systems use cutting-edge vision technologies and machine learning to detect defects, inconsistencies, and dimensional variations in real time. Integrating these systems into your blow molding process helps you achieve 100% inspection coverage, improve quality assurance, and reduce the risk of costly product recalls.

Ready to transform your blow molding with automation? Remember, a well-planned project takes time, but the rewards are substantial. Let us address your questions and guide you to success. Learn more about the common anti-automation arguments, why they shouldn’t hold you back, and how DEVELOP can optimize your blow molding for peak efficiency and quality.

Maintenance and Repair Automation

Minimizing downtime and ensuring optimal machine performance are critical for maintaining production efficiency. Automation solutions support proactive maintenance and repair strategies.

Automated Diagnostics

Automated diagnostics systems continuously monitor your equipment, detecting potential issues before they lead to costly breakdowns. By analyzing data from sensors and machine logs, you can identify early warning signs, predict maintenance needs, and optimize your maintenance schedules.

Keep your automation running smoothly! Read our Guide to Essential Maintenance and Upgrades for Automated Systems and discover how DEVELOP’s predictive maintenance solutions can help you minimize downtime, optimize performance, and extend the lifespan of your valuable equipment.

Smart Manufacturing Solutions for Plastics

The future of plastics manufacturing is intelligent, automated, and data-driven. DEVELOP LLC is committed to growing your business with the plastics industry automation technology you need to thrive in this dynamic landscape. Our robotic solutions for plastics are more than just machines. They’re strategic investments in your company’s growth, efficiency, and sustainability.

We understand that each plastics manufacturer has unique challenges and goals. That’s why we offer tailored automation and plastics industry solutions designed to meet your specific needs. Our team of experts will work closely with you to understand your processes, identify areas for improvement, and develop a customized automation strategy that aligns with your vision.

Take the first step towards a more efficient future by taking our free Automation Assessment Questionnaire. This quick survey will help us understand your unique needs and provide you with personalized recommendations for automation solutions.

Our Automation Assessment Services go beyond the questionnaire. You can also receive a comprehensive analysis of your operations, identifying potential automation targets and outlining the benefits you can expect. Plus, you’ll have access to a dedicated expert who will guide you through the entire process, ensuring a smooth and successful transition to automation.

Don’t miss out on this opportunity to transform your plastics manufacturing operations. Contact DEVELOP today and let us help you unlock the full potential of your business.