DEVELOP‘s unique Datron M8 Cube CNC has been used to produce high-quality parts for years. One of its significant limitations is that we must machine all threads with a thread mill. Still, thankfully CAMWorks offers robust “threading” capabilities in their software package- along with TechDB’s quick and reliable programming capabilities.

The TechDB contains generic strategies for the most common thread standards, but today we’re going to walk through how to create a library of your own. This is an excellent way to save time and provide clarity in programing by selecting specific parameters with just one click!

The TechDB application provides a simple way to build your library of thread milling parameters. This can be done by creating new libraries within the Thread Definition page and defining individual threads with unique names for each threading operation. The thread geometry should be defined under the feature condition tab. The Major Diameter, Minor diameter, and Pitch can all be found in many reference texts on machining. Still, they may need adjustment depending upon how your special tooling works to be accurate for real-world use with those specific machines or equipment!

A critical step in creating safe and reliable thread milling operations is establishing your minimum, maximum depth for features. If this is not defined, it can result in tool paths that may damage tools or workpieces. Once you’ve determined what parameters will give an ideal setting after all variables are accounted for, then start adding processes just like any other CAMWorks-enabled process would do

Depending on the size and tolerance of thread, reaming or boring operations may need to be added. We prefer contouring, milling minor diameter holes for our machining centers, saving tool magazine spots! Define your hole-making tools as you would for a hole operation, either using a predetermined tool assembly or using a function. We prefer to use a predetermined tool assembly to reduce potential machining errors.

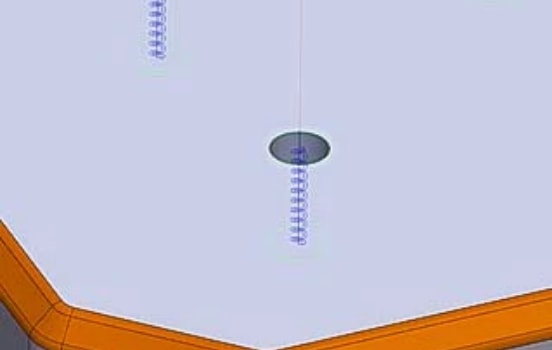

Once your hole-making solution has been defined, and all your parameters have been verified, create a thread milling operation. We strongly recommend using a predetermined tool assembly for this. Allowing CAMWorks to select the tool based on a function can lead to sub-optimal tool selection, which adds time and risk to programming. With the correct tool chosen, you can define the operation parameters. These are best determined by consulting the tooling manufacturer’s resources and real-world testing. Parameters such as Lead-In and Lead-Outs can often be left at the defaults of “Automatic,” but you may wish to adjust them in specific scenarios. The thread milling operation will now be available for use in your next CAD/CAM project.

To program a thread milling operation within CAMWorks, you’ll start by creating a Hole feature. Within the “End Conditions” tab of the feature creation menu, you’ll select “Thread” from the strategy drop-down. Verify that your depths are correct and accept the feature.

The created feature will likely default to a tapping operation using CAMWorks default operations plans. To use the thread milling operation plan you created, simply open the parameters menu by right-clicking on any feature and selecting “Parameter.” In this new dialog box that pops up, click ‘Thread Milling’ from within its list of choices. You will then select the thread condition and operations you defined within the TechDB by clicking “Library” and scrolling through the options until you find the thread condition you created. Click on the thread condition to select it and accept your choice by clicking ‘Okay.’ You can now generate an operation plan with correct toolpath parameters for this specific condition.

Within the TechDB

- Create your thread library within the TechDB

- Define your thread geometry for each thread you wish to thread mill.

- Create an operation for hole-making within each thread definition.

- Create thread milling operations for each thread definition.

Within CAMWorks

- Create a Hole Feature, selecting thread as the strategy.

- Within the parameters menu for the feature, select thread milling.

- Within the parameters menu for the feature, open the library and select the thread definition you created in your TechDB.

- Generate the operation plan and verify your toolpath parameter.