One of the most time-consuming, expensive, and detail-oriented aspects of the part machining process is 3D profile programming. This process oftentimes requires additional communication with machinists and manufacturers when specific surface finishes and design textures are required. Not to mention, improperly programmed 3D surfaces lends way to underutilized machines, wasting countless hours in the process.

Although CAMWorks Automatic Feature Recognition (AFR) cannot inherently identify complex 3D features, CAMWorks Library Objects can program 3D strategies via color matching. Putting knowledge into application, the DEVELOP team applied a color-based programming process by assigning colors to a range of proprietary textures and features.

Design to Manufacturing

DEVELOP’s internal design guide defines several applications, best practices, and strategies to apply colors to define 3D features found within their library. In essence, the library serves as an intermediary between design and manufacturing, promoting greater momentum between processes by removing communication errors. For machinists, the colors serve as an indicator that shows when specific CAMWorks features are already saved. From there, the machinists apply and verify tool depths on a feature-by-feature basis. Overall, the library can automate 80% of the programming process for any given 3D feature.

In practice, CAMWorks has successfully alleviated most programming errors, produced greater product homogeneity from a design and aesthetic standpoint, and yielded greater reliability. As for any process, input drives output. A robust TechDB and versatile library require teams to create and save value-adding color strategies.

Embedding Strategies into Your Library

- Determine which features and strategies you use most often.

- Within your design guide, assign feature colors and strategies.

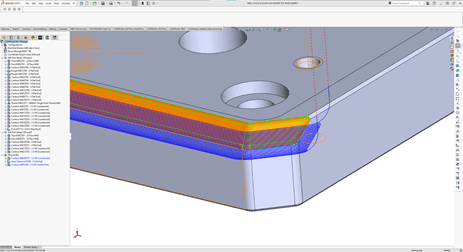

- Create generic feature variants to serve as a reference for your design and programming personnel (use filleted chamfer reference part below as an example).

- In CAMWorks, define the features via “Faces by Color” and program the operations as you normally would before saving the operations to your TechDB.

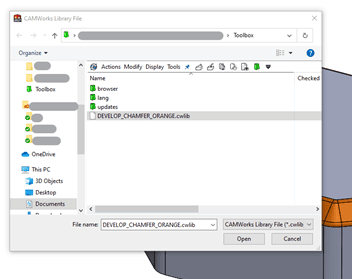

- Add a Library Object of the programmed features while including any necessary Avoid Features. Next, make this Library Object available to your programmers by saving it in your shared ToolBox.

- Document the feature and associated color within your internal records.