In the industrial manufacturing sector, staying competitive is a constant battle. Rising labor costs, supply chain disruptions, and the ever-increasing demand for faster, higher-quality production can feel like an uphill climb. Margins are tight, and every decision counts.

But what if there was a way to not only alleviate those pressures but also unlock untapped potential for growth? That’s where industrial automation comes in. By integrating industrial robotics and automation solutions, you can transform your manufacturing processes, boost efficiency, and gain a competitive edge.

At DEVELOP LLC, we understand the unique challenges you face. We’re not just automation experts, we’re problem solvers, ready to tailor industrial automated solutions that address your specific pain points. Whether you’re struggling with labor shortages, inconsistent quality, or simply want to optimize your automated production lines, we have the experience and expertise to guide you toward a more efficient and profitable future.

Ready to Reimagine Your Manufacturing? Download Our Free Automation Assessment eBook Now!

Robotic Applications For Industrial Manufacturing

Robots are transforming the way industrial manufacturing operates. Their versatility and precision make them ideal for a wide range of industrial applications of robots. Let’s explore some of these industrial automation applications in more detail.

Palletizing

Robotic palletizing systems are an industrial automated solution that offers a reliable and cost-effective way to automate the repetitive and physically demanding task of palletizing. By using robotic arms equipped with specialized grippers, manufacturers can achieve precise and consistent stacking of products, leading to increased efficiency and reduced risk of workplace injuries.

Robotic Palletizers

These industrial automated machines are versatile systems suitable for various product types and configurations.

Hybrid-Robotic Palletizer

Combining the benefits of robotic arms and conventional palletizing equipment for enhanced flexibility.

Bag-In-Box Palletizers

Specifically designed for handling bag-in-box products.

Case Palletizers

Optimized for stacking cases and cartons.

Robotic De-Palletizer

Efficiently unloading pallets for further processing or distribution.

Let DEVELOP’s automation experts analyze your current processes and identify opportunities for improvement.

Label Applicators

Labeling is a critical part of product identification and traceability. Robotic label applicators ensure precise and consistent placement of labels on boxes and pallets, eliminating errors and improving overall product presentation. This is an essential component of process automation in manufacturing.

On-Box Label Applicators

Ideal for applying labels directly onto individual products or boxes.

On Pallet Label Applicators

Designed to label entire pallets for efficient shipment and tracking.

Case Erectors

Efficient case erection is essential for packaging lines. Robotic case erectors automate the process of forming and sealing cardboard boxes, increasing throughput and reducing labor costs, making them high-value industrial automation equipment.

Robotic Case Erectors

Utilizing robotic arms for flexible and adaptable case erection.

Dedicated Machine Case Erectors

Specialized machines for high-speed case erection of specific box sizes.

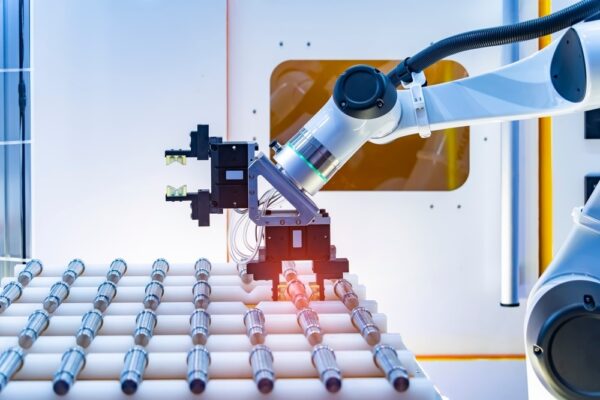

Pick and Place

Robotics in manufacturing has revolutionized pick and place operations, enabling precise and efficient handling of objects in a wide range of industries. Pick and place robots are indispensable for a wide range of industrial applications, from industrial material handling to assembly. These robots excel at picking up objects from one location and placing them in another with speed and accuracy, making them a core component of manufacturing automation systems.

Robotic Arm

These industrial robots are versatile arms with multiple joints and grippers for handling various objects.

Cartesian

Linear robots ideal for repetitive tasks requiring precise movement along multiple axes.

Delta

Parallel robots are known for their high speed and accuracy in pick and place applications, especially in industries like industrial robotics for electronics manufacturing.

Fast Pick

Specialized robots designed for ultra-fast picking and placing of small items.

Collaborative

These ‘cobots’ are designed to work safely alongside humans, sharing tasks and improving overall productivity. This collaborative approach is a key trend in industrial automation and robotics.

SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots are a high-value option for pick-and-place applications in industrial manufacturing. Renowned for their speed, precision, and compact footprint, SCARA robots excel at repetitive tasks that require fast cycle times and accurate positioning.

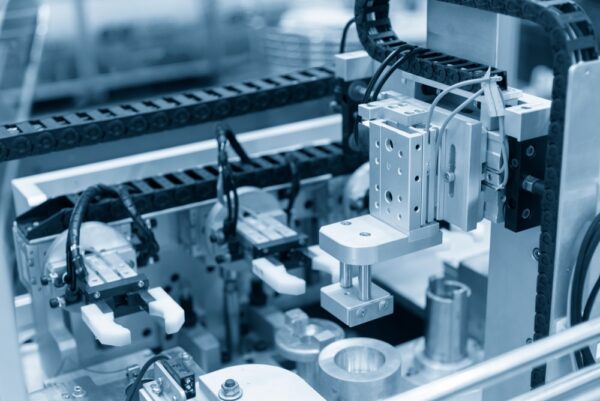

Assembly

The integration of robotics in manufacturing has transformed assembly lines, allowing for complex tasks to be completed with speed, accuracy, and consistency, ultimately improving product quality and reducing defects.

Robotic assembly systems have changed the way products are put together. They handle complex assemblies with precision and consistency, leading to improved product quality and reduced manufacturing costs. This is a prime example of how robotics in industrial manufacturing is changing the sector.

Continuous Transfer System

A continuous flow of products moves through the assembly line with minimal downtime.

Synchronous Transfer System

Each assembly station operates in sync, ensuring precise timing and coordination.

Asynchronous Transfer System

Each station operates independently, allowing for flexibility and adaptability.

Dial-type Assembly Machine

A rotating table with multiple stations for efficient assembly of small parts.

In-Line Assembly System

Products move along a linear path, with each station performing specific tasks in sequence. This is a versatile system suitable for various product types.

Carousel Assembly System

Similar to a dial-type but larger and with more stations, offering higher throughput for complex assemblies.

Single-Station Assembly Cell

A compact, self-contained unit designed for simple assembly tasks or when space is limited.

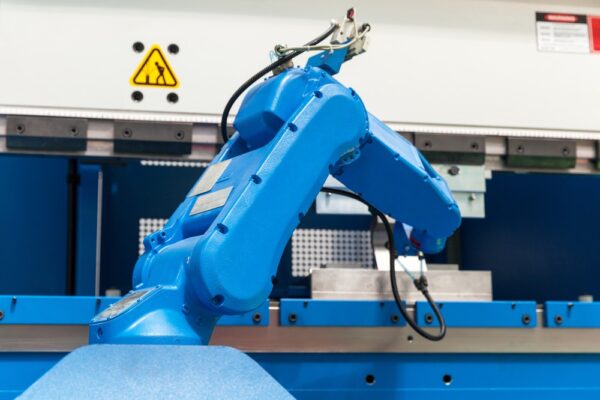

Machine Tending

Machine tending is a critical but often repetitive task in industrial settings. Robots in manufacturing have proven to be invaluable for machine tending applications. They tirelessly load and unload parts from machines, increasing uptime and productivity while minimizing the risk of human error.

Automating machine tending with robots, a form of CNC machine automation, frees up human workers for more complex tasks, improves safety, and ensures consistent operation.

Automated CNC Mill

Loading and unloading parts from CNC mills, optimizing production cycles and reducing downtime.

Automated CNC Lathe

Efficiently managing parts for CNC lathes, increasing throughput and maintaining consistent quality.

Automated Insert Molding

Precisely loading inserts into molds, ensuring accurate and efficient molding processes.

Automated Overmolding

Streamlining the overmolding process for improved production efficiency and product quality.

Automated Press Brake Machine Tending

Safely and accurately handling sheet metal parts for press brake operations, reducing the risk of operator injuries.

Material Handling

Efficient industrial material handling is essential for smooth operations in any industrial facility. Automated material handling systems, such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), can optimize the movement of materials, reduce labor costs, and improve safety. These industrial material handling solutions are integral to modern manufacturing automation.

AGVs (Automated Guided Vehicles)

Pre-programmed vehicles that follow fixed paths to transport materials.

AMRs (Autonomous Mobile Robots)

Intelligent robots that can navigate dynamically and adapt to changing environments.

Conveyors

Continuous systems for moving materials along a fixed path.

Robotic Material Handling

Utilizing robotic arms or other robotic systems to pick, place, and transport materials.

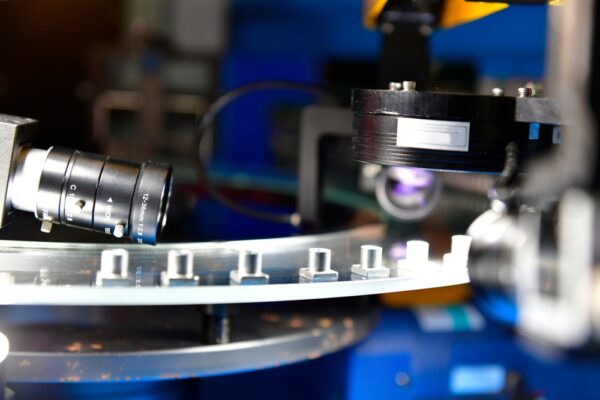

Quality Inspection

Ensuring product quality is critical in industrial manufacturing. Automated quality inspection systems, typically using machine vision technology, can rapidly and accurately inspect products for defects, inconsistencies, or deviations from specifications. This is a crucial application of industrial robotics and automation for maintaining high standards.

Attribute Inspection Automation

Checking for the presence or absence of specific features or characteristics.

Dimensional Inspection Automation

Measuring and verifying the dimensions of products to ensure they meet tolerances.

Machine Vision Technology In Inspection Automation

Utilizing cameras and image processing algorithms to detect defects and anomalies.

Packaging

Packaging is the final step in the manufacturing process, and it’s crucial for product protection and presentation. Robotic packaging systems offer speed, flexibility, and precision, ensuring that products are packaged efficiently and consistently. This is another area where robotics in manufacturing is making a significant impact.

Parallel Robots

Known for their high speed and accuracy in pick and place operations for packaging lines.

SCARA Robots

Ideal for assembly and packaging tasks requiring fast and precise movements in a horizontal plane.

Articulated Robots

These types of industrial robots are versatile with multiple joints, suitable for complex packaging tasks and palletizing, offering flexibility for various packaging needs.

Your Gateway to Industrial Automation Solutions

The impact of robotics in manufacturing cannot be overstated. From streamlining production lines to improving quality control and reducing labor costs, robotics is paving the way for a more efficient and competitive future for industrial manufacturers.

Industrial manufacturing is constantly evolving. Embracing industrial automation technologies isn’t just about staying competitive, it’s about entering a new era of possibilities. By partnering with an experienced industrial automation systems integrator like DEVELOP LLC, you gain access to a wealth of expertise and a proven track record in delivering industrial automation robotics solutions that drive tangible results.

Whether you’re looking to optimize your existing processes, implement the industrial robotic solutions with the fastest ROI, or explore the potential of industrial robotics for electronics manufacturing, DEVELOP LLC is your trusted partner in tackling the complexities of industrial automation and robotics. We offer comprehensive industrial automation services, from initial consultation and design to implementation and ongoing support.

Don’t let outdated processes hold you back. Embrace the power of manufacturing automation and unlock a future of increased efficiency, improved quality, and enhanced competitiveness.

Ready to Transform Your Operations?

Download our free eBook, Automate to Elevate: Your Automation Assessment Guide, to gain valuable insights into the potential of automating your industrial processes.

Alternatively, unleash your manufacturing potential with our free Automation Assessment Questionnaire. Discover hidden opportunities, optimize your operations, and drive bottom-line results. Don’t miss out on this chance to revolutionize your business.