In the world of electronics manufacturing, staying ahead of the curve demands agility, precision, and efficiency. Miniaturization of components, stringent quality requirements, and the pressure to deliver high-volume production under tight deadlines are constant challenges.

This is where DEVELOP LLC excels. We specialize in designing and building automated electronics assembly and manufacturing solutions that revolutionize how electronics are handled. Our expertise in electronics manufacturing automation and hardware engineering allows us to design and implement electronics automation systems that streamline processes, reduce costs, and enhance product quality.

Not sure if automation is right for your business? Try our free Automation Assessment questionnaire and get instant insights into the possibilities for your workplace.

Robotic Applications for Electronics Industry Manufacturing

Need to optimize your post-PCB assembly processes? Whether it’s PCB inspection, packaging, or palletizing, our expertise in industrial electronics automation and robotics can help. Automated solutions are designed to enhance your operations and deliver a clear return on investment, ensuring your business thrives.

Testing Solutions

Need to optimize your post-PCB assembly processes? Whether it’s PCB inspection, packaging, or palletizing, our expertise in industrial electronics automation and robotics can help. Automated solutions are designed to enhance your operations and deliver a clear return on investment, ensuring your business thrives.

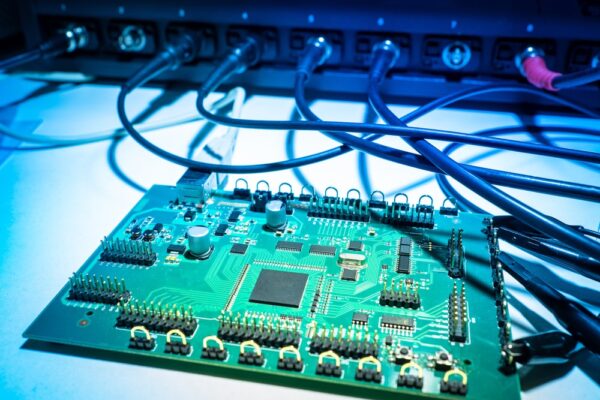

In-Circuit Testing (ICT)

A common method for testing individual components and their connections on a PCB, ICT systems use a bed of nails fixture to make contact with test points on the board. They then apply electrical signals to measure various parameters, such as resistance, capacitance, and voltage. You can automate this process, reducing testing time and improving accuracy. Automated systems can be programmed to test a wide range of components and configurations, ensuring comprehensive coverage.

Functional Testing

Functional testing assesses the overall performance of a completed electronic assembly. This means simulating real-world operating conditions and verifying that the product meets its intended specifications. Functional testing solutions can also be tailored to your specific product requirements. We can develop custom test fixtures and software to automate the testing process, ensuring your products are thoroughly tested before they leave the factory.

Material Handling and Transfer

Efficient material handling and transfer are essential for optimizing workflow and reducing manual labor in electronics manufacturing. Put simply, automated material handling in electronics solutions accelerates the movement of components, PCBs, and assemblies throughout the production process, improving efficiency and reducing the risk of damage.

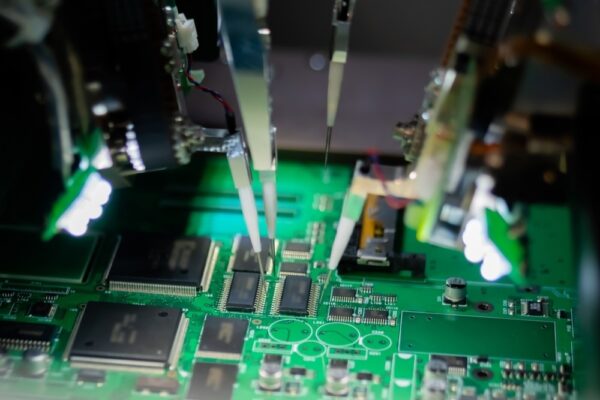

Robotic Pick and Place for Electronics

Pick and place robots are the workhorses of electronics assembly automation. Robotic pick and place systems are designed to handle PCBs post-assembly. Automated systems accurately and rapidly pick up PCBs and place them into housings or other systems, or prepare them for packaging or assembly with exceptional precision. Automation delivers high-speed, high-accuracy placement and can be customized to meet the specific needs of your production line, including integration with existing equipment and software.

Post-Assembly Automation Solutions

Efficient material handling and transfer are essential for optimizing workflow and reducing manual labor in electronics manufacturing. Automated post-assembly solutions streamline various stages of your production process.

Thermal Compound/Adhesive Dispensing

Adhesives play a vital role in securing components onto PCBs and within housings. Automated adhesive dispensing systems offer precise control over the amount and placement of adhesive, guaranteeing strong and reliable bonds that can withstand the demands of various operational environments.

To meet the specific needs of each application, selecting the appropriate dispensing system, nozzles, and programming parameters is crucial. A tailored approach optimizes adhesive application, minimizes waste, and ensures consistent bonding quality.

Final Assembly

After a PCB or embedded board is assembled, robotic systems seamlessly integrate them into the final product. This includes a wide range of tasks, such as meticulously screwing components into place with precise torque control using automated screw driving systems, applying different types of adhesives for secure and reliable bonding, and carefully picking and placing delicate electronic components with accuracy.

Turnkey automation solutions can handle a vast array of component shapes, sizes, and weights, ensuring consistent and reliable assembly regardless of the complexity of your product.

CNC Routing

Automated CNC machining solutions, such as gantry routing equipment, offer a precise and efficient method for de-paneling printed circuit boards (PCBs). Computer-controlled cutting tools on these machines accurately separate individual PCBs from larger panels, ensuring clean separation and minimal damage. This approach improves production speed and yield while minimizing material waste.

In addition to clean cuts, CNC routing systems can be programmed to drill holes, add slots, or create other intricate features required for the final PCB layout and design. This versatile capability makes CNC routing a valuable asset for electronics manufacturers seeking to streamline their PCB production processes.

CNC Routing

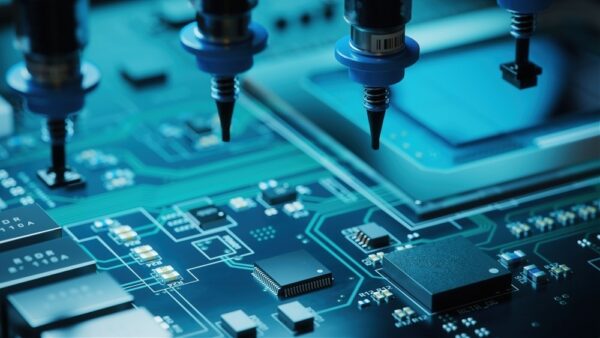

For complex or high-density PCB assemblies where manual soldering is impractical or prone to errors, robotic soldering systems excel. These systems use precise robotic arms equipped with specialized soldering tools to create reliable solder joints with unmatched consistency and speed. By automating this critical process, you not only minimize defects such as cold joints, bridging, and excess solder but also significantly reduce production time and labor costs.

Robotic soldering systems are programmable to handle a wide range of solder types, component sizes, and board configurations, making them adaptable to your specific manufacturing needs.

Storage and Retrieval

Efficiently managing the vast array of electronic components used in modern manufacturing is a challenge. Automated storage and retrieval systems (AS/RS) transform your inventory management. These systems use robotic shuttles, vertical lift modules, or carousels to store and retrieve components with speed and accuracy. By automating this process, you minimize human error, reduce the risk of misplacing or damaging components, and optimize your warehouse space.

AS/RS can be integrated with your existing inventory management software, providing real-time visibility into your stock levels and automating replenishment orders.

Packaging and Palletizing

The final stages of your electronics manufacturing process are just as important as the first. Robotic packaging and palletizing systems streamline the handling and preparation of your finished products for shipment. These systems use robotic arms equipped with specialized end-effectors to pick, place, and arrange products into boxes or onto pallets with precision and speed.

These systems can be configured to handle a variety of packaging types and sizes, ensuring that your products are securely packed and ready for distribution. Palletizing solutions optimize pallet loading patterns, maximizing storage space and reducing shipping costs.

Additional Automation Capabilities

In addition to the core solutions mentioned above, DEVELOP offers a wide range of additional robotic solutions for electronics manufacturing, addressing various aspects of the production process:

- Automated Screw Driving and Fastening Systems: Robotic systems for precise and efficient screw driving and fastening, including automated screw placement solutions and high-speed screw fastening automation, ensuring consistent torque control and secure assembly.

- Component Insertion and Assembly: Robotic systems for screwing, fastening, and press-fit assembly.

- Coating and Encapsulation: Automated conformal coating and potting solutions for protection and reliability.

- Packaging and Labeling: Robotic solutions for automated packaging and label application.

Your Path to Electronics Manufacturing Excellence Starts Here

The electronics industry is constantly evolving, and to thrive, you need a partner who understands the intricacies of advanced automation technologies for electronics. DEVELOP LLC is that partner. We’re not just a provider of electronics manufacturing machines; we’re a catalyst for innovation, helping you to achieve unparalleled levels of efficiency, quality, and productivity.

This isn’t a distant dream, it’s a reality within reach. Take the first step toward transforming your electronics manufacturing operations by completing our Free Automation Assessment Questionnaire. This quick set of questions is designed to assess your unique situation, needs, and goals, providing a roadmap for personalized automation solutions.

Our Automation Services go beyond a simple questionnaire. We look deep into your manufacturing processes, exploring various electronics automation systems and strategies to pinpoint your ideal automation targets. You’ll have the dedicated support of one of our experienced automation experts, who will guide you through every step of the journey.

Don’t let your competition outpace you. Embrace the future of electronics manufacturing automation with DEVELOP LLC. Contact us today to start your transformation.