The food and beverage industry is constantly evolving, with consumer demands and safety regulations becoming increasingly complex. Automation provides a powerful solution to meet these challenges, improving efficiency, safety, and consistency across the entire production line. From automated food processing systems that streamline production to food manufacturing robots that handle repetitive tasks with precision, automation is transforming how food and beverage companies operate.

Discover the potential of food and beverage automation to optimize your production line, improve product quality, gain a competitive edge, and grow your business.

Not sure if automation is right for your business? Take our free Automation Assessment and get instant insights into how choosing the right automation solutions for the food and beverage industry can deliver rapid ROI.

Robotic Applications For Food And Beverage Production

Robotic automation is changing food and beverage production. From raw ingredient handling to final packaging, robots can perform tasks with speed, precision, and hygiene that would be difficult or impossible for humans to achieve.

Food and Beverage Packaging

Packaging is a critical step in food and beverage production, ensuring product safety and freshness. Automated packaging systems, including food packaging robots, can handle a wide variety of formats.

Raw Food

Robots can precisely portion and package raw meat, poultry, fish, and produce, minimizing contamination risks.

Cooked Food

Ready-to-eat meals, baked goods, and snacks can be packaged efficiently by robots, maintaining product integrity and extending shelf life.

Beverage

Bottling, canning, and carton packaging of beverages are streamlined with robotic automation, increasing throughput and reducing waste.

Tray Packaging

Robotic systems excel at placing products onto trays for presentation and protection.

Canned Food

High-speed robotic canning lines ensure consistent filling and sealing for optimal preservation.

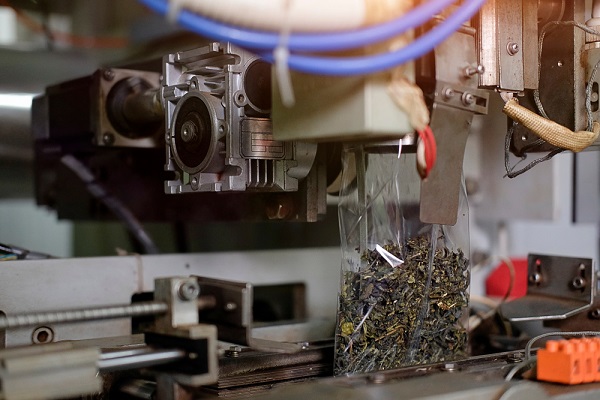

Bagged Food

Robots can accurately fill and seal bags of various sizes, from snacks to bulk ingredients.

Boxed Food

Automated boxing systems can erect, fill, and seal boxes of various dimensions, improving productivity and reducing labor costs.

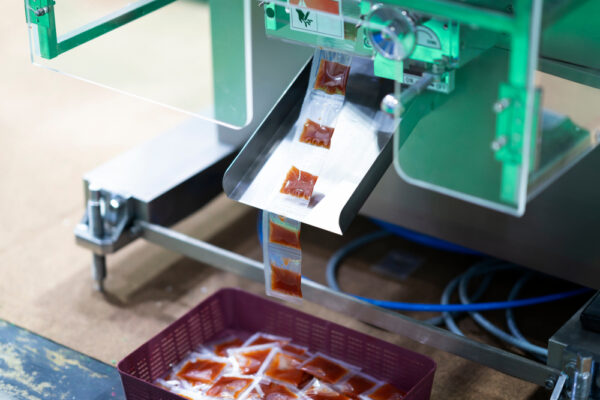

Pouches

Flexible packaging formats like pouches can be filled, sealed, and labeled by robots, offering versatile packaging solutions.

Sorting Systems

In the food and beverage industry, efficient sorting is essential to maintain product quality and streamline production. Robotic sorting systems, powered by advanced vision technology and food manufacturing robots, offer the following applications.

Color Sorting

These systems can accurately sort products based on color variations, ensuring consistent appearance and identifying potential defects.

Size and Shape Sorting

Robotic sorting systems can categorize products by size and shape, separating different varieties or identifying irregularities that could indicate quality issues.

Barcode Scanning

By reading unique barcodes on products, you can quickly and accurately sort items based on SKU, production lot, or destination, enhancing traceability and inventory management.

Quality Control Inspection Systems

Ensuring food safety and quality is a top priority for food and beverage manufacturers. Automated quality control inspection systems play a crucial role in achieving this goal.

Defect Detection

These systems use cameras, sensors, and food industry automation systems to identify defects such as cracks, dents, or missing labels.

Foreign Object Detection

X-ray and metal detection technologies integrated into inspection systems can detect foreign objects like metal fragments, glass shards, or plastic pieces.

Label Inspection

Cameras and vision systems can verify label accuracy, including barcodes, expiration dates, and ingredient information.

Weight and Fill-Level Inspection

Checkweighers and fill-level sensors ensure product consistency and compliance with regulations.

Picking and Placing Systems

Picking and placing systems are the workhorses of food and beverage automation. They offer versatility and speed in handling a wide range of products.

High-Speed Picking

Robotic arms with specialized grippers can pick and place items at incredible speeds, ideal for tasks like packing snacks, chocolates, or small bottles.

Vision-Guided Picking

Using cameras and software, these systems can identify and pick irregular items like fruits, vegetables, or baked goods from a conveyor or bulk bin.

Case Packing

Robots can efficiently arrange products into cases, ensuring optimal space utilization and minimizing damage.

Kitting and Assembly

In meal kit production, robots can assemble the individual components into the final package.

Order Fulfillment

For e-commerce or direct-to-consumer sales, robots can pick and place orders from warehouse shelves into shipping containers.

Baked Goods and Candies

Baked goods and candies are fragile products that require careful handling. Robotic automation solutions for these products include a range of industrial applications.

Packaging

Robots can gently pick and place baked goods or candies into trays, boxes, or bags without damaging them.

Decorating

Specialized robots can apply icing, frosting, or other decorations to baked goods with precision and consistency.

Sorting and Packing

Vision-guided robots can sort baked goods and candies by type or size and pack them into appropriate packaging.

Front-of-Line Automation

Front-of-line automation is critical for optimizing the start of the food and beverage production process. By automating front-of-line tasks, manufacturers can improve efficiency, reduce labor costs, and enhance overall productivity.

Line Charging

Robotic systems automate the process of loading raw materials or ingredients onto production lines, ensuring a continuous and efficient flow.

Depalletizing

Robots equipped with specialized grippers can safely and efficiently remove products or raw materials from pallets, reducing manual labor and the risk of injury.

End-of-Line Automation

End-of-line automation is essential for streamlining the final stages of food and beverage production, ensuring efficient packaging, palletizing, and distribution. By incorporating robotic systems into these processes, manufacturers can achieve higher throughput and improved product quality.

Flow Wrapping

Robotic flow wrapping systems can quickly and consistently wrap products in protective film, extending shelf life and maintaining product freshness.

Packaging

Robotic packaging systems can handle a variety of packaging tasks, including cartoning, bagging, and labeling.

Packaging

Food palletizing robots automate the process of stacking products onto pallets for shipment, improving efficiency and reducing labor costs.

Depanning

Robotic depanning systems gently remove products from trays or conveyors, minimizing damage and maximizing product yield. These systems are particularly useful for handling delicate baked goods or frozen food products.

Robotic Depanners

Equipped with advanced vision systems and grippers, robotic depanners excel at delicately lifting and removing even the most fragile baked goods. Frozen items and pastries from trays or conveyors can be moved with minimal product damage and maximum yield.

Vacuum Depanners

When it comes to flat-surfaced products like cookies or crackers, vacuum depanners are the tool of choice. Their powerful suction cups provide precise, damage-free removal, ensuring a smooth and efficient depanning process.

Vision-Guided Depanners

Combining the power of robotic automation with cutting-edge vision technology, these systems locate and identify products with laser-like precision. This ensures the most accurate and efficient removal, regardless of product type or tray configuration.

Hybrid Depanners

For manufacturers seeking the ultimate flexibility, hybrid depanners offer a versatile solution. By integrating multiple technologies, such as vacuum suction and vision guidance, these systems can deftly handle a wide array of product types and configurations, optimizing the depanning process for maximum efficiency.

Traceability and Tracking

Traceability and tracking are essential for ensuring food safety and supply chain visibility. Robotic systems can play a key role in traceability efforts.

Anti-Counterfeit Packaging

Robots can apply security features such as tamper-evident seals or unique identifiers to packaging, helping to prevent counterfeiting.

Label and Lid Inspection

Vision systems can inspect labels and lids for accuracy and integrity, ensuring that products are properly labeled and sealed.

Transform Your Food and Beverage Production with Automation

By adopting the power of robotic solutions and automated systems, you can access whole new levels of productivity. Automation is more than just efficiency and quality. It’s about gaining a competitive edge. It’s about innovating faster, adapting to changing demands, and differentiating yourself in a crowded marketplace. With automation, you can expand your production capacity, reach new markets, and ultimately drive significant growth for your business.

Don’t let this opportunity pass you by. Take the first step towards transforming your food and beverage production with DEVELOP LLC. Fill out our free Automation Assessment Questionnaire today. Our team of experts will carefully analyze your unique needs and goals, and then provide you with personalized recommendations to unlock the full potential of automation for your company.