The cosmetics industry faces relentless pressure to deliver high-quality products at competitive prices while meeting stringent safety and regulatory standards. Automation plays a pivotal role in achieving these goals, allowing cosmetic manufacturers to streamline production, minimize errors, and enhance overall efficiency.

DEVELOP LLC’s expertise in designing and implementing custom-built turnkey automated systems allows cosmetic companies to integrate advanced packaging solutions and robotic handling systems for optimized production lines.

Industrial Applications of Automation in Cosmetics Manufacturing

Automation transforms various stages of cosmetic production, from ingredient handling and formulation to filling, packaging, and labeling. By incorporating high-speed product packaging solutions, cosmetic manufacturers can achieve faster production rates and increased throughput. Automation in cosmetic production also ensures consistent product quality, reduces waste, and improves worker safety.

Filling and Packaging

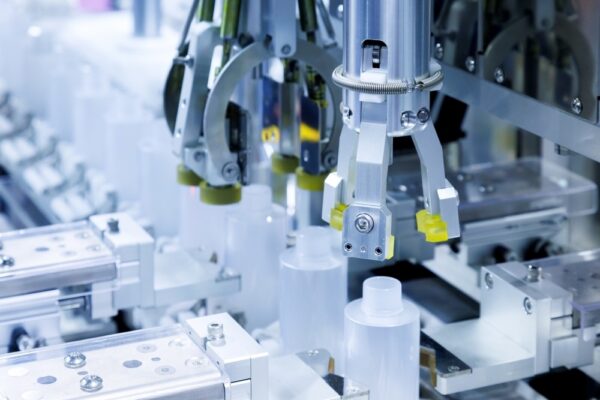

In cosmetics and personal care products manufacturing, speed and precision are paramount. Automation solutions for filling and packaging cosmetics ensure that products are handled with care, filled accurately, and packaged securely, maintaining the highest standards of quality and presentation.

Packaging Solutions for Personal Care Products

In cosmetics manufacturing, ensuring product integrity and presentation after the filling process is paramount. DEVELOP offers automated packaging machinery for cosmetic production, tailored to the specific needs of various product types.

Whether it’s unit-dose blister packaging for samples or high-speed cartoning and case packing for efficient distribution, our solutions streamline the packaging process.

Advanced machine vision solutions ensure fill level accuracy, identifying and rejecting any underfilled or overfilled containers. With seamless cosmetic and personal care packaging line integration, we boost efficiency and maintain product quality throughout the entire manufacturing process.

Cosmetic Packaging Machine

Blister packaging and clamshells are popular choices in the cosmetics and personal care industries, offering both product protection and an attractive presentation.

DEVELOP specializes in providing blister packaging automation solutions, ensuring accurate and efficient filling of these packaging types. Our automated blister packaging machines precisely dispense creams, gels, liquids, or even powders into individual cavities, creating unit-dose or sample-sized packages ideal for travel or promotional purposes.

We also offer solutions for filling clamshell packaging, a versatile option for various personal care items.

Beyond mere efficiency, blister packaging and clamshell filling automation represents a strategic investment in product quality and consumer confidence.

When even the slightest imperfection can impact consumer perception, investing in blister packaging automation is a decisive step towards securing a competitive edge in the cosmetics and personal care market.

Cap Lining and Wadding Equipment

Cap lining and wadding equipment automates the insertion of protective liners and wadding into cosmetic containers. This process safeguards product integrity by preventing leaks, contamination, and evaporation.

It also adds a layer of tamper evidence, assuring consumers of product authenticity. Automated insertion of liners and wadding improves efficiency, reduces the risk of human error, and maintains product quality.

Labeling and Packaging Personal Care Products

Accurate and attractive labeling is crucial for brand recognition and consumer confidence. Automation in labeling and packaging personal care products guarantees that each item is clearly identified, complies with regulations, and is ready for retail shelves.

Labelers for Cosmetics

Labelers are critical in the cosmetics industry to ensure accurate and compliant product labeling. These machines apply labels containing essential product information, barcodes, and branding to various packaging formats. Advanced labelers integrate label and barcode verification systems to identify and reject mislabeled or unreadable codes, ensuring product traceability and regulatory compliance.

Fully automatic stretch wrapping systems also secure palletized products for safe and stable shipping, minimizing damage during transport.

Packaging Machinery for Cosmetic Production

Efficient and flexible packaging solutions are vital for cosmetic manufacturers to meet diverse product and market demands. Packaging machinery for cosmetic production covers a range of automated systems tailored to specific product needs. Personal care packaging solutions accommodate various container shapes and sizes, ensuring optimal product presentation and protection.

By automating the packaging of personal care products, manufacturers can increase throughput, reduce labor costs, and minimize errors. Cosmetic and personal care packaging line integration also enables seamless product flow from filling to final packaging, optimizing overall production efficiency.

Robotic Handling and Assembly in Cosmetic Production

From delicate components to finished products, robotic handling and assembly systems offer unparalleled precision and efficiency. These systems enhance the assembly process, reduce errors, and ensure consistent product quality.

Robotic Picking Personal Care Products

Robotic picking systems are indispensable in modern cosmetic manufacturing for efficient and gentle product handling. Cosmetics pick and place robots use advanced vision systems and precise end-of-arm tooling to accurately pick and place products of various shapes and sizes.

Depalletizers automate the unloading of incoming pallets, reducing labor requirements and improving safety. On the other end of the production line, palletizers efficiently stack finished products onto pallets for shipping and distribution.

These robotic handling systems improve productivity, minimize product damage, and accelerate material flow throughout the manufacturing process.

Component Assembly

Component assembly in cosmetics manufacturing often involves intricate and delicate tasks that require precision and consistency. Automated systems equipped with feeding and orienting systems efficiently handle and position components for assembly. Indexing and continuous assembly systems synchronize the movement of components and tools, ensuring smooth and streamlined assembly processes.

Robotic handling systems further enhance accuracy and speed, particularly for complex or fragile components. These automation solutions optimize component assembly operations, improving product quality and reducing production time.

Additional Applications of Automation

in Cosmetics Manufacturing

Beyond the primary processes of filling, packaging and palletizing, labeling, and assembly, automation extends its transformative capabilities to many other aspects of cosmetic manufacturing, ensuring efficiency, quality, and innovation.

- Efficient Component Feeding: Centrifugal feeder bowls and vibratory feeder bowls automate the precise and consistent feeding of components like caps, pumps, and applicators to assembly lines, minimizing downtime and maximizing throughput.

- Uncompromising Quality Control: Cosmetic defect detection systems use advanced machine vision solutions in cosmetic manufacturing to identify imperfections, inconsistencies, and contaminants in real-time, ensuring only flawless products reach consumers. Foam volume and density analysis guarantees consistent product texture and performance.

- Tailored Automation Solutions: Every cosmetic manufacturer has unique requirements and challenges. Personal care and cosmetics automation solutions can be customized to address specific needs, ensuring seamless integration and optimal performance within existing production environments.

These additional applications of automation demonstrate its versatility and value in enhancing every aspect of cosmetic manufacturing. By adopting these technologies, manufacturers can unlock new levels of efficiency, quality, and innovation, positioning their brands for success in the cosmetics market.

Transform Your Cosmetic Production with Automation

To stay ahead in the cosmetics industry, manufacturers must embrace innovation and efficiency. Automation in cosmetic production provides the tools to achieve these goals, offering precision, speed, and consistency that manual processes cannot match. From filling and packaging to labeling and assembly, automation transforms every stage of cosmetic manufacturing.

By partnering with DEVELOP LLC, you gain access to custom-built turnkey automated systems tailored to your unique production needs. Our expertise in advanced machine vision solutions in cosmetic manufacturing and robotic handling systems allows you to optimize your operations, reduce costs, and enhance product quality.

Are you ready to unlock the full potential of automation in your cosmetic manufacturing facility?

Download our free eBook Automate to Elevate: Your Automation Assessment Guide to uncover the secrets of automation and access tools that will transform your operations. Learn the DIY assessment process and explore DEVELOP’s proven methodologies.

Or, take our complimentary Automation Assessment Questionnaire. This short survey is designed to quickly assess your needs and set the stage for personalized automation solutions.

Embrace automation today and take your cosmetic brand to new heights.